61. Shaker motors

The shaker motor is one of my favorite feedback toys. It does what

the name suggests: it shakes the cabinet when activated. When done

properly, the effect is a deep rumble that reverberates

through the floor like an earthquake. Appropriately, the first arcade

pinball that featured a shaker motor (as far as I know) was

the earthquake-themed Earthshaker (Williams, 1989).

Stern has enthusiastically embraced shakers in recent years, offering

them as optional equipment in nearly all of their titles since 2010.

Shakers were rare in the arcade before that, appearing only in a few

titles where there was some kind of thematic connection, such as

Earthshaker (for obvious reasons) and Red and Ted's Road

Show (for the demolition theme). I think Stern realized that the

tactile effect is a lot of fun for its own sake, even when it doesn't

particularly tie in to the theme, which is exactly why shakers are

popular in virtual cabs. You can profitably work it into pretty much

any game, even older games that didn't have shakers in their original

arcade versions. The DOF Config Tool database takes this to heart,

liberally adding shaker effects to lots of older tables - as of this

writing, the DOF database uses the shaker in 237 (!) games. Of

course, DOF also faithfully reproduces the authentic usage in games

like Earthshaker that actually did have shakers originally. If

you include a shaker, it will get plenty of use.

Theory of operation

A shaker is simply a motor with an unbalanced weight attached to the

shaft. It's like a washing machine a big heavy load on spin cycle.

Off-the-shelf pinball shakers

You can buy ready-to-use pinball shaker units from the pinball parts

vendors, including Marco Specialties and Pinball Life.

Off-the-shelf kits sell for $100 to $200, depending on the target

machine type.

The different kits currently available all use exactly the same shaker

mechanism (as far as I can tell). The only reason there are so many

different kits is that each comes with an interface board that works

with a particular type of Stern machine. For a virtual cab, you

actually don't need an interface board at all, because your DOF output

controller will perform that function instead. So any of the Stern

kits should work, and I'd just buy the cheapest one you can find,

currently around $100. When the kit arrives, just throw away the

Stern interface board, and plug the motor directly into your feedback

device controller; see Wiring below.

Off-the-shelf vibration motors

There's another off-the-shelf option that's less expensive than the

Stern shaker kits: replacement "vibration motors" for massage chairs and

similar appliances. Some people on the forums have tried these

and reported generally positive results.

You can find these on Amazon, eBay, and Aliexpress. Some are as

little as $20. They're all no-brand parts from third-party sellers

that come and go overnight, so I can't give you any specific model

numbers or product links, but you can find options by searching the

retail sites for vibration motor. Look for devices that have

two counterweights and a speed of 4500 RPM or less. Lower speeds are

better - higher speeds will feel too much like buzzing.

Be aware that there are smaller and larger versions of these motors.

The smaller ones are more like cell phone buzzers, so skip those. You

want one of the larger ones, sold for applications like massage

chairs.

Even the largest vibration motors I've found still use smaller

counterweights than the Stern units, so they'll produce a weaker

shaking effect. I've seen a couple of negative comments about this

from virtual cab builders. But stronger isn't necessarily better;

there's an element of taste to this, plus, a less powerful unit might

be more suitable if your cab is smaller and lighter than a full-sized

pinball machine.

DIY designs

Shakers are simple enough that you can build one yourself for about

$50 to $100 in parts. That's not much of a cost savings compared to

buying one of the ready-made Stern kits, and it's actually more

expensive than buying an OEM vibration motor, but some people might

want to build their own just for the enjoyment of the project. A DIY

shaker also gives you more control to tweak the effect to your liking, by

adjusting the amount of weight and the geometry.

Hare are some detailed DIY plans you can find online:

- My shaker design

- Darkfall's plans on vpforums

- RacerRik's plans on Pinside

- Waldo34's plans on Pinside (a variation on RacerRik's plans)

The two Pinside plans closely replicate the mechanical design of the

Williams and Stern shaker units (which are themselves nearly

identical), so they yield nicely professional-looking results, but

they're challenging to build because they require cutting, drilling,

and thread-tapping steel bar stock. They also require some

sheet-metal work. You need some specialized tools for all of that

metal working, and the steel bar stock itself is rather expensive.

Darkfall's design is easier to build because it doesn't require any

metal fabrication, and it doesn't require any especially exotic parts.

The first shaker I built was based roughly on Darkfall's design, and

it works nicely. My only criticism is that its method for attaching

the weights to the motor shaft is a bit jury-rigged and seems

precarious - although, to be fair, the one I built has held together

for many years now. My own design is an attempt at a more elegant and

robust way to attach the weights, while still being easy and

inexpensive to build. Almost all of the parts required in my plan are

common hardware store items, and the only things you have to fabricate

yourself are some simple plywood pieces.

Designing your own shaker

If you prefer to develop your own DIY plan, here are some parameters

you can use as a starting point, based on what seems to work in

practice for the commercial units and the DIY designs:

- Around 3000 RPM for the spin rate

- About 350 gram-centimeters (5 ounce-inches) of off-balance weight

The "gram-centimeters" figure refers to the result of multiplying the

total weight of the counterweights by the distance from the shaft to

the center of mass of the counterweights. It's the product of these

two numbers that matters, so you should get the same effect from a 100

gram weight at 3.5cm or a 350 gram weight at 1cm, for example.

For reference, the counterweights in most of the commercial shakers

are steel bar stock, 3/4" wide x 3/4" thick x 2" long, weighing 140g

each. The shaft is placed 1/2" from the center of the long dimension

(2").

Selecting a motor for a DIY unit

The motor is the hardest part to find when building a DIY shaker unit.

There are hundreds (maybe thousands) of types of small electric

motors available online, but most are unsuitable for one reason

or another - they're too big, too small, use too much

power, etc. It's especially hard to find all of the right properties

in a dual-shaft configuration, since there just aren't that many

dual-shaft motors available. A dual-shaft motor isn't an absolute

requirement, but all of the DIY designs call for one, because it's

easier on the motor's bearings to divide the weight into two smaller

chunks than to have a single large counterweight.

The easiest way to source a suitable motor, by far, is to buy one that's

marketed specifically as a replacement motor for a pinball shaker

unit. Those are more expensive than comparable generic motors

from eBay or Aliexpress, but you can be confident that they're

suitable for the task, and you won't have to comb through hundreds of

listings looking for the right specs. The pinball parts vendors

currently (2022) stock several such motors:

- Pinball Life - replacement motor for Stern shaker kits

- Marco Specialties - replacement motor for Stern shaker kits

- Marco Specialties - replacement motor for 1990s Williams shakers, part 14-7951

If you want something less expensive, or you just enjoy the hunt,

here are the properties to look for in a generic motor:

| Parameter | Range | Comments |

|---|---|---|

| Configuration | Dual-shaft (also called double-shaft) | This means the rotating shaft sticks out at both ends of the motor, allowing you to attach a weight at each end. |

| Voltage | 12VDC | Most DC motors will run on a wide range of voltages (e.g., 6V-24V), so just make sure that the power supply you plan to use is within the voltage range listed for the motor. 12VDC is usually the most convenient power source in a pin cab. |

| Power | 20W-50W | The power rating gives you an idea of the mechanical force that the motor can muster, and the load it places on the power supply. A motor rated for 20-50W should have enough mechanical power for strong shaking, with a power draw at 12V of 4A or less. That's in the range that most ATX power supplies and high-power DOF controllers can safely handle. Motors with higher wattage ratings might overload your power or control systems. |

| Speed (no load) | 3000-4500 RPM | Higher speeds might feel more like buzzing than rumbling. |

| Shaft diameter | 4mm-6mm or 1/4" | This won't affect the feel of the effect, but smaller shafts might bend under the force of the shaking. |

For reference, here are some specific motors that virtual cab builders

have used successfully in the past. It's probably impossible to find

anything on this list that's more than a couple of years old - the

manufacturers generally seem to do a single large production run for

each model, and once that's sold out, they're gone. But it might

still be worth checking, since you can sometimes the older models as

remnants and used items on eBay.

- Generic 775 12V/24V 50W dual-shaft motor (available on Amazon and Aliexpress as of June 2022; note that the "775" is not a model number or brand, but is simply a standard designation for the motor's dimensions; many other "775" motors are available that look similar but which have very different electromechanical characteristics)

- Pittman 9414H255-R2 (last seen around 2015)

- Buehler 480-0211-01 (last seen around 2015)

If you know of any other specific motor models that I should add to the

list, please let me know.

Historical note: The motor in the original Williams shakers was

labeled Johnson HC970. Unfortunately, that's not very helpful for

finding replacement parts, because Johnson Electric apparently used this

designation for a number of different OEM parts that they

custom-manufactured for different customers. I've seen a couple of

reports on the forums from people who found Johnson HC970 motors

on eBay that turned out to be unsuitable.

Converting a regular motor to dual-shaft

Most shaker unit designs call for dual-shaft motors. But dual-shaft

motors are relatively rare. This is the main thing that makes it so

difficult to source a motor for a DIY shaker unit. One way around

this to buy a regular motor, and convert it to a dual-shaft

configuration.

This isn't exactly an easy solution. It requires taking the motor

apart, modifying its inner workings, and putting it back together in

working order. You'd have to be comfortable doing major repair work

on mechanical appliances to contemplate this, and you should only

consider it if you can tolerate the risk that you'll destroy the motor

in the process. Most small DC motors are not at all designed to be

taken apart by the end user. Attempt this only with a cheap motor that

you don't mind replacing if you end up breaking it.

The basic idea is to disassemble the motor and replace its original

shaft with a longer one - long enough to stick out from both ends of

the motor body. The full procedure is beyond what I can document

here, especially because motors aren't all exactly the same on the

inside. There are some Youtube videos on the subject that you might

find helpful - try searching for convert motor to dual shaft.

Here's just a rough outline of the process:

- Open the motor casing. This usually requires using vise grips or pliers to forcibly bend back some metal tabs that hold the two halves of the main outer casing together. (I did warn you that most motors aren't designed to be taken apart!)

- Remove the whole armature/shaft assembly. Before you do, you might want to take a bunch of close-up pictures, to record how the brushes, springs, bearings, etc. are all arranged, so that you can get it all back together later. Beware that the brushes are usually spring-loaded, so small parts might go flying when you remove the shaft. You might want to work the motor inside a box or plastic bag so that flying parts don't get lost.

- Remove the shaft from the armature. In most motors, the shaft is

simply press-fitted into the armature (the part with the wire coil

windings), meaning that the only thing holding it in place is

friction. Removing it just requires some brute force to

pull or hammer it out. The fit is usually very tight, so this can take

quite a bit of force.

If the shaft is long enough to start with, you might not need to replace it at all. You might be able to simply reposition the armature along the shaft so that some of the shaft sticks out the back of the motor.

- Assuming you do need to replace the existing shaft with a longer one, you'll now need to cut a piece of round steel rod to the desired length to make the new shaft. You'll need steel rod of exactly the same diameter as the original shaft. You can buy steel rod stock from Amazon or a hardware store. Cut it to the desired length, probably about 1" to 2" longer than the original shaft, using a cut-off wheel, hacksaw, etc.

- Apply some thread-locker to the new shaft so that it'll stay in place. Insert the new shaft into the armature, and position it so that enough material will stick out on each side of the motor body to provide attachment areas for the counterweights on both ends. As with removing the shaft, this is a brute-force matter of pushing or hammering it into place.

- Put the motor back together and bend the casing lock tabs back into place.

Enclosure

A shaker needs a sturdy cover that will contain the weights in case

they ever come loose. A detached weight could become a high-speed

projectile that could cause a lot of damage if not contained.

The off-the-shelf pinball shaker units all come complete with their

own plastic enclosures, so that's another point in their favor. If

you build a DIY plan, or buy one of the generic vibration motors

mentioned earlier, you'll need to provide your own enclosure. I'd

suggest a simple hand-built plywood box. (A clear acrylic cover is a

nice enhancement if you build your own box, since it lets you safely

observe the shaker in operation whenever you want to check that it's

working properly.) You could also re-purpose a plastic food container

or storage box, if it's strong enough to contain an ejected weight.

Where to mount

On the real machines that have shakers, the units are installed

somewhere near the front of the cabinet, but the exact location varies

by title. I think it's just a matter of what's convenient in that

machine's cabinet layout. Most of the recent Stern machines place

the shaker in one of the front corners, alongside the coin box. In

other machines, the shaker is behind the coin box, either centered

left-to-right or off to one side.

I don't think there's much difference in effect from the different

placement options, so put it wherever you have room. The only

imperative, I think, is that it's better to keep the shaker close

to the front of the cabinet, since that's where the player is.

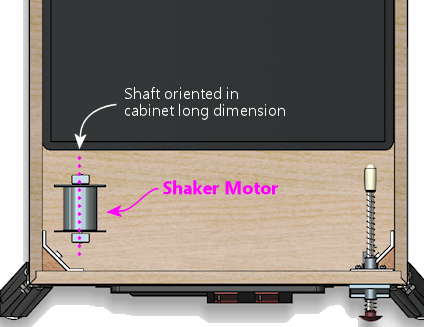

In every commercial pinball setup I've seen, the motor shaft is

oriented parallel to the long axis of the cabinet. I think this

orientation does matter, since it creates a side-to-side shaking

motion. That's probably the best direction for maximizing motion

transfer, given the cabinet's proportions.

Interaction with nudge devices

Some people have trouble with the nudge device picking up

accelerations from the shaker. The nudge device is an accelerometer

whose whole purpose is to detect cabinet motion, so it necessarily

detects the motion that the shaker causes the same way that it detects

motion from the player's nudges.

The shaker's motion shouldn't interfere with game action, even though

it registers on the accelerometer. The motion from the shaker is

different from nudges in that it's symmetrical, it's faster, and it's

lower amplitude. The back-and-forth shaking motion should essentially

cancel out on the time scale of manual nudging. Player nudges, in

contrast, tend to be bigger and in one direction, and they happen on a

longer time scale.

If you're having a problem with your nudge device going crazy when

your shaker is on, there are two ways to address it:

- Turn down the intensity of the shaker

- Turn down the sensitivity of the nudge device

Before taking either action, you should ask yourself: What would a

real pinball machine do? In other words, would that same exact shaker

motor affect the ball on a real pinball machine the way it's affecting

your virtual game? If the answer is yes, then the shaking effect is

probably too intense, and the solution is to reduce the shaker

motor speed. Shakers on the real machines don't send the ball flying

around. If your shaker is at a level where it wouldn't affect the

ball on a real machine, but it's affecting the virtual game to a

troublesome degree, then the problem is in your nudge sensor

calibration: you've turned up the sensitivity to unrealistic levels.

I'd always start by adjusting the shaker to produce a tactile effect

you like, ignoring its effect on your nudge sensor. The easiest way

to adjust the shaking intensity is to adjust the speed of the motor,

either by adjusting the voltage or by adjusting the DOF PWM

parameters; see "Speed adjustment" below. If you built a DIY shaker,

you might also be able to change the shaking intensity by increasing

or decreasing the amount of weight in the counterweights.

If the shaker is still causing excessive nudge interference after

you've adjusted the intensity of the tactile effect to your liking,

the next step is to adjust the sensitivity of your nudge device. You

might balk at this suggestion, but go back to that question about real

machines: does the ball fly around wildly on a real machine when the

shaker is on? No, it doesn't. The thing is, most virtual cab

builders initially set their nudge devices to be far too sensitive.

This is natural - you want to see an immediate and obvious effect from

the new toy. But it's easy to overdo this. I always urge new cab

builders to go find a physical pinball machine and play around with it

for a while, to see how the ball reacts in reality. If you mostly

play virtual pinball, you'll probably be surprised by how "dead" a

real machine feels when you nudge it. On a real machine, a ball trapped

on the flipper will not fly up off the flipper when you give

the machine a little push, the way many people think it's supposed to

work in Visual Pinball. If you want the shaker to coexist peacefully

with your nudge device, you'll have to adjust your nudge device

sensitivity so that it's closer to the subdued response a real

ball would show.

One more thing: please don't use "dead zones" in your accelerometer

setup. Dead zones are terrible. They make erratic behavior even more

erratic because they create a non-linear "cliff" where there's no

response at all at one level, and suddenly a huge response just a hair

above that. It's better to stick with purely linear settings, like the

"Gain" settings in Visual Pinball.

For more on nudge adjustments, see Nudge & Tilt.

Speed adjustment

The amount of shaking you get out of your motor is a function of

the weights, the distance they are off-axis, and the speed of the

motor. It also depends on factors that aren't related to the

motor itself, like where it's mounted in the cabinet, the overall

weight of your cabinet, the stiffness of the legs, and the

construction of the floor the machine is sitting on. The same shaker

motor will produce somewhat different effects in different cabinets.

Of all of these factors, there's one that we can easily change: the

speed of the motor. Once you have everything set up, you can

fine-tune the effect by adjusting the motor speed up or down.

There are two ways to control the motor speed: adjusting the voltage

of the power supply, and adjusting the power in software via PWM

control (Pulse Width Modulation - a method of varying the power level

in a digital circuit by rapidly switching the power on and off).

Adjusting the voltage: Most DC motors will work with a range of

power supply voltages, spinning faster at higher voltages and slower

at lower voltages. You can take advantage of this to adjust the

motor's speed by varying the power supply voltage.

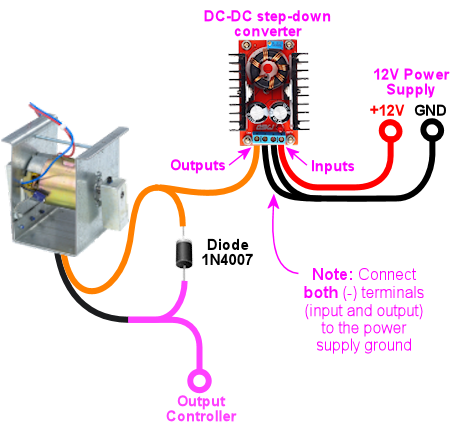

The best way to control the voltage is to connect an adjustable

voltage regulator between the motor's power input and the 12V supply,

as shown in the diagram below. Look for a "DC-to-DC step down

converter" on eBay, and find one that has a dial or set-screw that

sets the output voltage. This will let you adjust the voltage to

anywhere between 0V and 12V, so that you can fine-tune the motor speed

to your liking.

Select a regulator that has an amperage rating high enough for the

motor (equal to or higher than the amperage the motor draws).

Note that a motor always has a minimum voltage level, below which it

won't have enough torque to start spinning. The exact minimum is

something you have to determine experimentally, since it depends upon

the amount of load the motor is driving. If you try a low voltage and

the motor stalls, don't leave the power on very long, as a stalled

motor can quickly overheat. When experimenting to find the right

voltage, it's safest to start with the dial turned up to the high end

(12V), and gradually reduce the voltage until the speed is to your

liking.

Typical wiring for a shaker motor with a DC-to-DC step-down

voltage regulator to adjust the voltage supplied to the

motor. Check your converter for the correct input/output

terminals (don't rely on the illustration - your converter

might have a different terminal arrangement). Note that

the converter's (-) input and output terminals are both

connected to the power supply ground.

Adjusting with PWM: The DOF Config Tool lets you set the power

range for the shaker motor. Go to the Port Assignments page, and look

for the "Shaker Motor" section on the right side of the page. This

will let you set a maximum intensity, on a 1-48 scale. The default

is level 48, to run the motor at full speed. Lower settings should

slow down the motor; you can try different settings until you find

a speed you like.

Most motors have a minimum power level they need to operate at all, so

there will probably be some minimum PWM value below which your motor

won't start. Don't leave the power on to the motor if it's stalled,

as that can overheat it. When experimenting to find the right PWM

level, it's safest to start at the maximum (48) and work down from

there until the speed is to your liking.

Note that the PWM control only works if you're using a PWM-capable

output controller, such as an LedWiz or Pinscape Power Board. PWM

won't work with a relay-based controller such as a Sainsmart. You'll

have to use the voltage adjustment approach with those.

Wiring

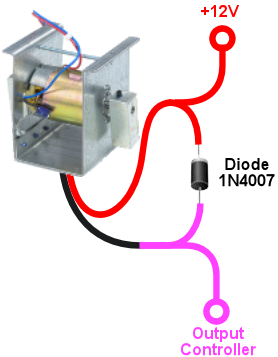

Follow the general wiring plan for any output device

(Feedback Device Wiring). Connect one terminal of the shaker

motor to the positive (+) power supply voltage (usually 12V). Connect

the other terminal to an available port on your output controller.

A diode is required, to protect your output controller and other

electronics from interference from the motor's magnetic field. See

Coil Diodes. If you're using a pre-built shaker assembly, it

might or might not already have a diode installed; if you don't see

one, assume there isn't one and add your own.

If you're using one of the off-the-shelf Stern shaker kits, and it

came with an interface board for a real pinball machine (for example,

a Stern SAM connector or a SPIKE connector), you won't need that

interface board to use the motor in your virtual cab. Those boards

are designed to interface to the specific electronics found in the

various Stern machines, so they're not relevant to a virtual cab. We

just need the motor itself.

If you're using the Pinscape expansion boards, you can connect the

shaker directly to any MOSFET Power Board port. If you're using an

LedWiz, don't connect the motor directly, as it will draw too much

power for an LedWiz port; you'll need some kind of booster or

amplifier circuit. See "Power limits and boosters" in

LedWiz Setup.

H-bridges: If you read through old posts on the forums, you

might see people say that you need an "H-bridge" to control a shaker

motors. You don't. The idea got embedded at some point in the

group consciousness because someone read about it on an Arduino forum

and it got repeated a lot. H-bridges are useful if you need to

control a motor bidirectionally, which is something that Arduino

robotics hobbyists often want, but isn't necessary with a shaker

motor. A shaker motor just needs to run in one direction, so you can

connect a shaker directly to any feedback device controller port that can

handle the motor's power level. If you're using the Pinscape

expansion boards, you can run a shaker motor directly from any Power

Board port. If you're using an LedWiz, you'll need a power booster

circuit, the same as you'd use for any other type of high-power

device like a solenoid or coil.

LedWiz hacks: You might also see old posts with some really

scary LedWiz modifications involving soldering wires to IC pins on the

LedWiz board. Ignore those. They're based on that old

H-bridge notion. If you're using an LedWiz, you will need some kind

of booster circuit, but that's something you can add on externally.

There's no need to modify the LedWiz in any way. You just need

the same sort of booster circuit you'd need for any other high-power

device, as described in Power

limits and boosters in LedWiz Setup.

Electrical interference

Motors produce a lot of electrical noise, which can feed back into the

power supply wiring and propagate into your system's logic circuits, such as the

feedback controller and even the PC motherboard.

Diodes are a must, as already mentioned, because they help suppress

the high-voltage transients that motors produce.

For some motors, diodes might not be enough. If you start seeing

noticeable glitches when the motor is running, such as USB disconnects

or random keyboard input, you might need some additional filter

components.

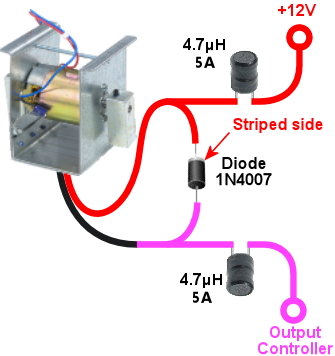

The typical noise filtering for a motor is to add a pair of "chokes"

(a type of inductor), in series with the wiring to the motor. Add one on

the power input to the motor and one on the connection to the feedback

controller.

Try a 4.7 µH inductor, with an amperage rating equal to or

higher than your motor's operating current. Here's an example

part from Mouser that should work well:

Coilcraft DR0608-472L 4.7µH, 5.8A radial inductor - at Mouser

Inductors aren't polarized, meaning they don't have a special

orientation when you install them. It doesn't matter which lead

connects to the "+" side and which connects to the "-" side.

(The diode, in contrast, has to be installed with its striped

side going to the "+" voltage, as shown in the diagram.)

The inductors shouldn't be necessary on most virtual cabs. I haven't

had a need for this with any motors on my machine. But it's something

to try if you experience interference problems that seem to

coincide with shaker activation. You can also add inductor

filtering to any other motor-based devices that cause interference,

such as gear motors, fans, and beacons.

Note that you should always keep the diode in place even when adding

inductor filters. The inductors provide a different type of filtering

and aren't a substitute for the diodes.

DOF Setup

In the DOF Config Tool, go to the

Port Assignments page. Find the port number where you wired the

shaker motor. Assign it to "Shaker".

At the right side of the page, you'll also find a section labeled

"Shaker Motor" that lets you set the intensity range. If you're using

a PWM-capable controller (e.g., an LedWiz or a Pinscape power board),

this lets you set the range of power that DOF uses when the shaker

runs. The intensity values are on a 1-48 scale, where 48 is the

highest power. The default settings use the full available range. If

you find that the shaking effect is too powerful when DOF activates it

during game play, you can reduce the maximum intensity setting to slow

down the motor. Similarly, if the motor seems too weak some of the

time, or doesn't have enough power to start spinning in some cases,

you can raise the minimum setting.

Note that the intensity adjustment won't work unless you're using a

PWM-capable output controller. If the motor is connected through any

kind of relay, such as a Sainsmart board, the DOF PWM adjustment won't

work and you'll have to adjust the speed some other way, such as with

a varying voltage supply (see "Speed adjustment" above).