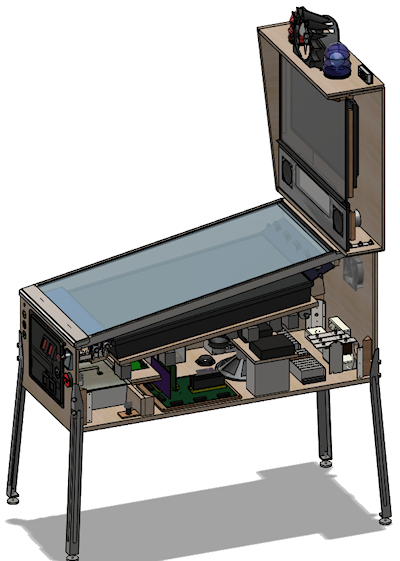

26. Inside the Cabinet

The modern virtual pin cab can be pretty complex on the inside. A

decked-out cab can actually have more equipment packed into it than a

real pinball machine, which is kind of perverse given that this is all

about software simulation. But it makes sense when you consider that

we're not just building a computer; we're building a computer/pinball

hybrid. The computer part by itself has more to it than most desktop

systems, because of the extra monitors and the specialized

input/output peripherals. And the pinball part includes a pretty

large subset of a real machine.

With so much to install, making everything fit can be a challenging 3D

puzzle. I'd like to be able to present a simple, one-size-fits-all

layout here, but that's not really possible. Pin cabs are too

individualized. But I can at least offer one possible solution. In

this section, we'll walk through a model pin cab that includes just

about everything I can think of, and look at where each major element

goes in this setup. The model takes into account the space constraints,

and it also follows my philosophy of serviceability, meaning that it's

designed so that everything can be accessed fairly easily for repairs

and upgrades, even after the machine is fully built.

The arrangement described in this section is based on my own cab, so I

consider many of the design decisions to be tried and true. It's not

an exact replica, though. I've made some revisions in an attempt to

improve things that weren't ideal in my original design. I also made

room for additional equipment that's not in my build. My cab is

pretty decked out, but for the purposes of this section, I've tried to

imagine an "ultimate" cab with all of the toys.

This is, of course, not the only possible solution to the question of

how to arrange things, and I'm sure it's far from the best solution.

Some of it might not work at all for your setup, given that you might

have completely different constraints from your PC packaging or TV

size. So I'll try to explain the rationale behind each element's

placement, so that even if you can't use the exact layout as

presented, you can at least gain some insight from it to use in

formulating your own layout.

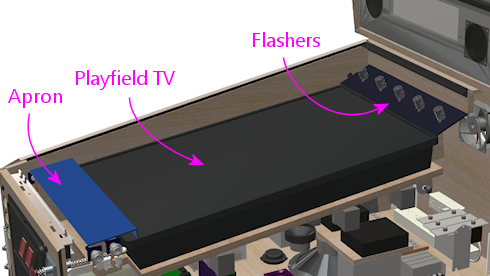

Playfield, apron, and flashers

These elements (or some subset of them) form the top layer in the main

cabinet.

The basic arrangement is pretty straightforward, but the details can

be surprisingly hairy. First, there's the placement of the TV: do you

place it flush with the top of the cab, or recessed like a real

playfield? How far in? At what angle? All the way at the front, or

set back to make room for the plunger? These are all among the most

frequent questions that new cab builders ask. You can see from the

diagram what I prefer, but this is a matter of aesthetics, and there

are other schools of thought. Second, once you've decided upon the

desired look, you still have to implement it physically. That's trickier

than it might look, especially if you want to fulfill my admonition to

make the machine serviceable (Serviceable Design).

Serviceability requires that the TV be easily removed. You can

probably guess I'm not in favor of just nailing it in there and

calling it done.

There's enough to this subject that we've given it its own chapter,

Playfield TV Mounting.

It's extremely important to plan out exactly where the TV goes before

you start arranging anything else inside the cabinet. The TV assembly

forms a ceiling that constrains the vertical space available to

everything else, so you need to know where that is.

If possible, you should actually install the TV early on, not just

make plans, so that you can see the space it delineates for real

rather than just as measurements. But don't do that unless you're

using a mounting that's easily removable, because you won't want the

TV in the way while you're installing everything else. If you use a

mounting system like the one I outline in

Playfield TV Mounting, you'll be able to install and remove

the TV with little effort.

Some notes on the flasher panel. I've depicted the back panel with

the traditional five flasher domes. Each is a clear plastic dome with

a 3W RGB LED inside. This is such a ubiquitous setup that the most

popular pinball software (Visual Pinball with DOF) is programmed to

assume it's there. However, some people replace the five-flasher

panel with an array of individually addressable LEDs - sort of a

coarse dot-matrix display. The physical setup for that is basically

the same; just remove the flasher domes and substitute addressable LED

strips or arrays. Some people also do both, by installing a

five-flasher panel as shown and adding an addressable LED strip or

two, across the top and/or bottom.

See Flashers and Strobes and Addressable Light Strips.

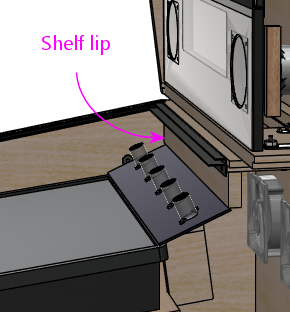

You could also fit one or more light strips across the "lip"

(illustrated below) that sits below the backbox shelf. Keep

in mind that there's a standard trim piece for the top glass that also

affixes here, so check how that will fit before finalizing plans.

See "Rear glass trim" in Cabinet Hardware Installation.

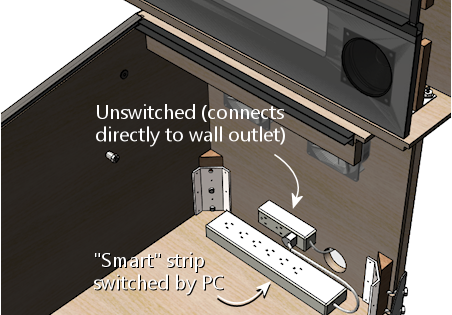

Power inlet

Okay, let's take the TV out and look inside the cab. We'll start with

some simple infrastructure: the power strips. I like to put these at

the very back of the cabinet.

Why at the back? For one thing, that's where the power cord

customarily comes in. For another, it's a really good fit for the

geometry: most power strips are long and narrow, which is a shape that

fits nicely along the bottom of the back wall. And finally, it's good

to put something low-maintenance back there, because that area is

relatively difficult to reach into once everything's assembled. The

very back is blocked from above by the backbox shelf, so it's a little bit

of an inconvenience to access. It's just reachable enough for

plugging and unplugging AC cords, but you wouldn't want to have to get

back there with tools if you can avoid it.

I recommend installing two power strips: a small strip that

you'll plug directly into the wall outlet, and a second, larger strip

that acts as a "smart" strip, providing power to its outlets only when

the PC is powered on. All of the accessories (the TVs, audio

amplifiers, and feedback devices) plug into the switched outlets,

which lets you turn the whole cab on and off with the PC soft power

controls. You can implement the switched outlets by buying a smart

power strip (they don't design them for pin cabs specifically, but

it's the same idea: they're for turning off your monitors and printers

when you're not using the computer), or by building your own. This is

all covered in much more detail in its own section,

Power Switching.

I'd put the large put strip along the base of the back wall, and mount

the smaller strip on the rear wall a little ways above. Put it high

enough up that it won't be in the way of the plugs on the main strip.

We have enough stuff to pack in here that it's important to think

three-dimensionally, so utilize wall space when it makes sense.

The power strips should be secured in place somehow. As always, I'd

avoid anything permanent, such as gluing them down: think

serviceability when choosing installation methods. Adhesive Velcro on

the bottom would be a good choice for the large strip mounted on the

floor. I wouldn't use Velcro for anything mounted on a

vertical surface; the glue on it doesn't hold up over time when under

constant tension from gravity. I'd use some sort of screw-in brackets

instead. Or you could build a little shelf for it (jutting out from

the rear wall), and Velcro it to the strip to the shelf.

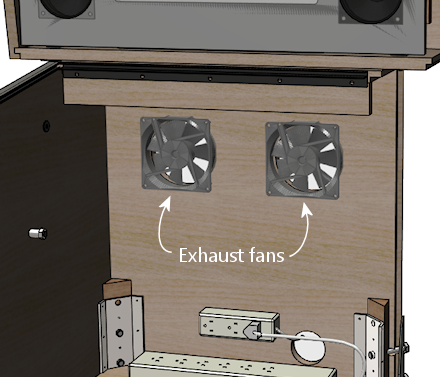

Rear exhaust fans

As long as we're looking at the back, don't forget the exhaust fans.

As mentioned above, the backbox shelf makes this area at the back

cumbersome to access when the cab gets fuller, so it's good to get

the fans in place early.

Rear wall exclusion zone

After installing the power strips and exhaust fans, there's still

a lot of open space on the rear wall. I'd recommend leaving

this space unused for now, for several reasons:

- It's hard to reach after the machine is assembled, as mentioned earlier, due to the way the backbox shelf overhangs this area

- There will eventually be a bunch of wires and cables that you'll have to route through this area from the backbox

- If you're using a liftable playfield TV mounting like the one outlined in Playfield TV Mounting, you'll need to keep most of this space open so that the TV has room to maneuver; plus, the TV overhang will make the space even harder to reach

After everything else is assembled, you can reconsider this space if

there's "just one more thing" you want to install and you can't find

space for it anywhere else. At that point you'll have a more concrete

idea of the constraints on this space, so it'll be easier to decide

if it makes sense to mount anything else here. In my cab, I find this

space so hard to access that I wouldn't put anything here besides

what we've already covered.

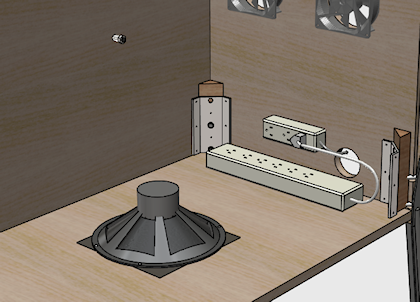

Subwoofer

The subwoofer's position is forced by where you placed the floor

opening for it. That should be installed next, so that you can take

it into account when positioning other things.

Most subwoofers have screw holes around the perimeter of the speaker

opening. Use suitable wood screws. If you're using a screen cover,

place it between the speaker and the cabinet floor. For a plastic

screen, you might want to pre-cut holes where the screws go; driving a

wood screw through the plastic can bend or twist the plastic.

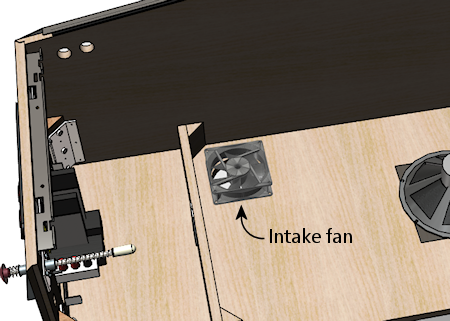

Intake fans

As with the subwoofer, the intake fan or fans are constrained to be

placed at the openings you made for them, so they should be installed

now to ensure that you don't create space conflicts for them later.

Most PC fans come in square mounting frames (like the one illustrated

above) with screw holes at the corners that you can use to secure the

fan to the cab floor.

Note that you can buy dust filters for PC fans. Since this is an

intake fan, it's a great place to put a filter, to reduce dust buildup

inside the cab. Place the filter between the fan and the cab floor.

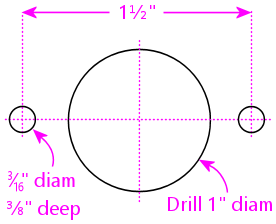

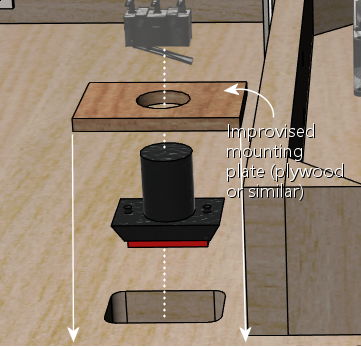

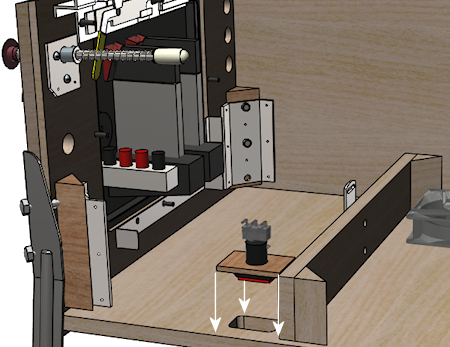

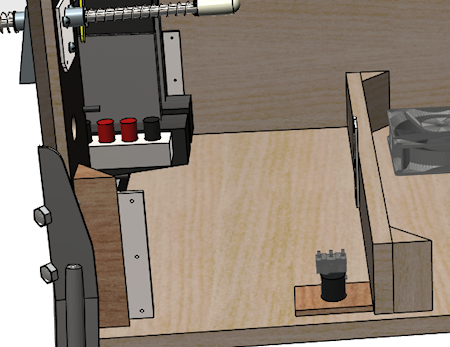

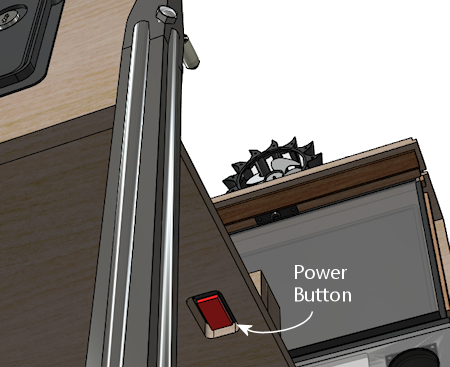

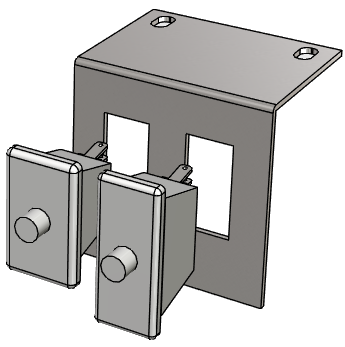

PC power switch

The SuzoHapp "large rectangular button" (part number D54-0004-5x) is a

good form factor for the main power button. It fits in the power

switch opening used in the standard WPC plans, and it's large enough

that it's easy to operate by feel (which is nice because it's hidden

on the bottom of the cabinet, so you want to be able to just reach

under and press it without having to see what you're doing).

You can install this type of button by creating a small mounting plate

using plywood or any other convenient material. Cut holes in the

mounting plate using the drilling template below, then assemble as

illustrated. Then simply screw the plywood mounting plate into the

cab floor from the inside. This will leave the button perfectly

recessed in the switch opening.

Drilling template for SuzoHapp large rectangular pushbutton

(part D54-0004-5x)

You can easily substitute any of the other similar SuzoHapp

pushbuttons (small round pushbutton, square pushbutton) if you prefer.

I like the large rectangular button because it fits the opening nicely

and it's large enough that it's easy to operate by feel, which is

helpful given the hidden location.

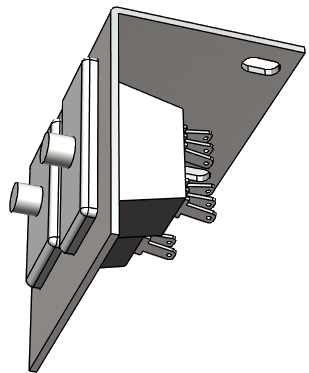

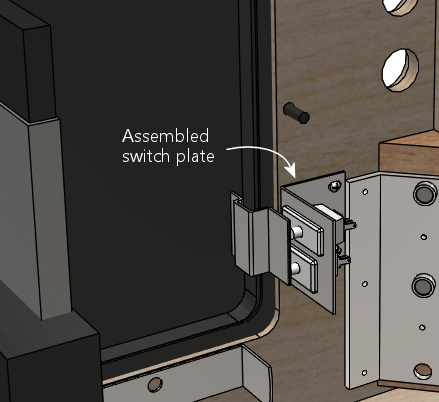

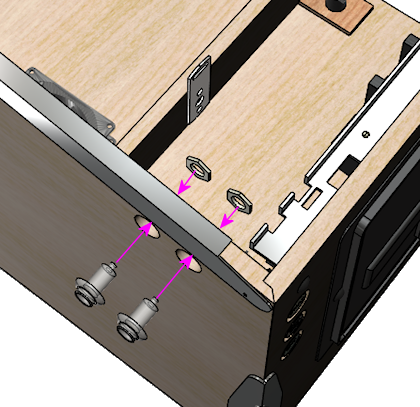

Coin door switch

On a real machine, there's a switch that senses whether the coin door

is open or closed. This is also useful to include on a virtual cab,

because some of the emulated ROMs use it to control access to the

operator menus. See Coin Door for more.

The coin door itself should have a pre-installed metal plate that acts

as an actuator for the switch. This is positioned at the bottom of

the door on the hinge side. It's attached to the door, so that it

swings out when the door opens.

There are different ways to mount a coin door switch (which you can

read more about in the Coin Door chapter), but my

recommendation is to use the standard pinball parts. They're

purpose-built for this, so they're easy to install and reliable, and

they're not particularly expensive. The standard parts consist of a

metal mounting bracket and a "plunger" switch. The bracket is

designed so that the plunger switch simply snaps - a couple of plastic

clasps on the switch hold in place.

Snap the switch into the plate, then mount the plate so that actuator

on the door presses the switch plunger all the way in when the door

is closed. The plate mounts to the front wall of the cab with

wood screws.

Note that the standard mounting plate has slots for two switches: a

large switch with six connectors, and a small switch with three

connectors. On the real machines, the large switch is used an

interlock to cut off high-voltage power to the playfield when the door

is open, and the small switch is connected to the CPU to let the

software know when the door is open. For a virtual cab, most people

don't bother with the high-voltage interlock, since we don't tend to

have any exposed high voltages to worry about in the first place. So

you probably only need one switch, for the software. The large or

small version will work equally well for that, so just install

whichever one you bought and leave the other slot in the mounting

plate empty.

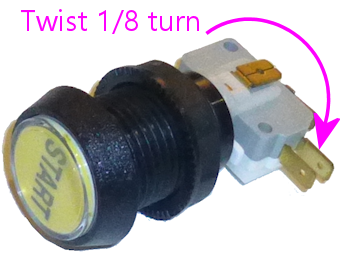

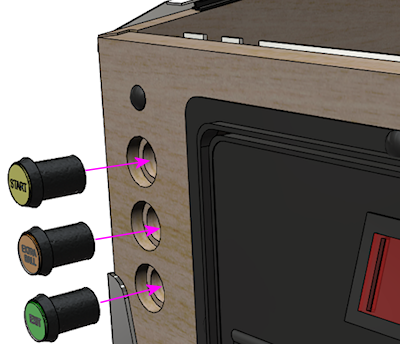

Front buttons

If you're using the common SuzoHapp "small round pushbutton"

assemblies, they're easy to install. Start by disassembling the

button. Gently twist the squarish base about 1/8 of a turn

to free it, then pull it out. Unscrew the nut

Now just insert the button through the front wall hole (from the

outside) and reverse the disassembly procedure: screw the nut back

onto the shaft, and pop the lamp base assembly back into place, giving

it a slight twist to lock it. The lamp base only fits in a certain

orientation, so just rotate it until you find the magic spot.

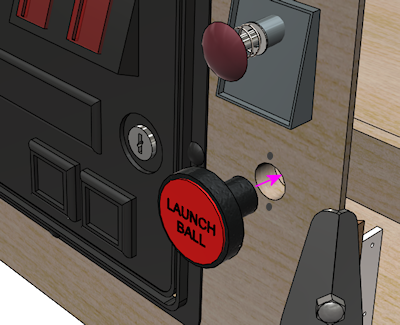

If you're installing a Launch Ball button, it works the same way.

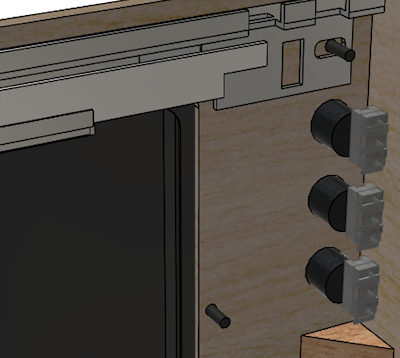

Flipper buttons

The flipper buttons simply fit through the holes and are fastened with

Palnuts on the inside. The rounded knob on the outside end of the

button tends to be a tight squeeze - I guess that's intentional to

keep them from getting wobbly over time. But it can take a little

effort to force them into the hole the first time you install them.

Seat them by applying pressure from the outside until the collars are

flush with the cabinet wall. (I wouldn't try to force them flush by

overtightening the Palnuts, since I'd be afraid of stripping the

plastic threads.)

Note that if you drilled the flipper button holes straight through at

1⅛" (which is what I recommend), the Palnuts will be about the

same size as the holes, so they won't clamp the buttons down very

well. Don't worry - this will be fine as long as you're using one or

both of the following:

- VirtuaPin leaf switch holders

- LightMite LED boards

If you're planning to install one of those, you can just leave the

Palnuts loose for now and come back to this later. If you're not

using one of those, and the Palnuts are too loose, you might need to

add a suitable washer.

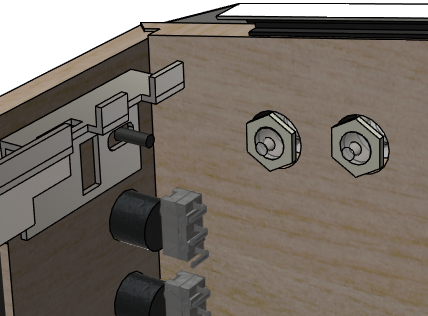

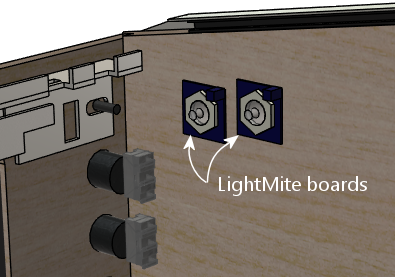

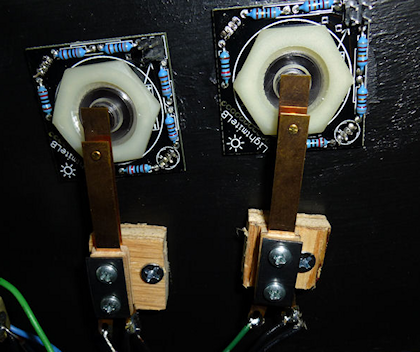

If you're installing the LightMite LED boards, they'll go under the

Palnuts as illustrated below. You'll need to assemble them with

LEDs and connectors first, so hold off on installing them if you

haven't gotten to that yet. See Button Lamps

for more.

If you're installing the VirtuaPin leaf switch holders, they also

install under the Palnut - it should be pretty obvious how those work.

If you're not using the VirtauPin leaf switch holders, you'll need to

mount the leaf switches to the cab wall instead. This takes a tiny

bit of improvisation.

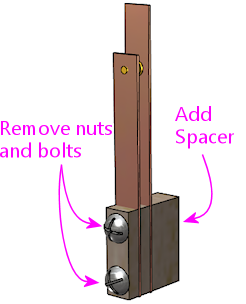

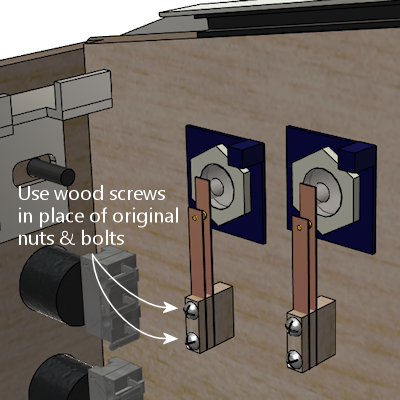

Here's what I did. The standard leaf switches have little insulator plates at

the bottom that separate the switch leaves. The whole thing is held

together by a pair of bolts fastened with nuts. To attach these to

the cab wall, you can take out the nuts and bolts and substitute wood

screws. Use screws long enough to pass through the whole leaf switch

assembly, with about 1/2" left over to screw into the cab wall.

That's almost all there is to it. But there's a slight snag:

the switches will be too close to the cab wall if you mount them

as-is. You need to add a little spacer to move them out from the wall

about a quarter inch. I found that ⅜" plywood was just about

right, so I cut some small (1" x 1") squares and used those as the

spacers.

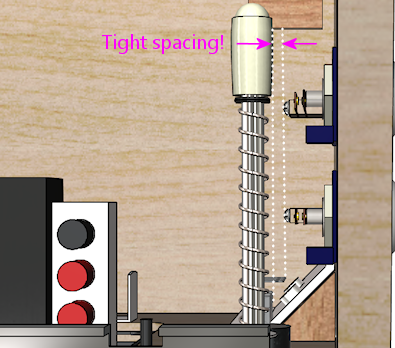

One last note before you actually install the switches. If you're

installing a plunger, spacing on the plunger side will be tight. The

flipper buttons happen to be positioned right alongside the plunger

rod.

On the real machines, they leave just enough room to make it work, but

we virtual people have an added challenge here, which is that we also

need to install a plunger position sensor of some kind. That can add

bulk around the plunger rod that isn't there on the real machines.

All of the commercial and DIY sensor designers know this is an issue,

and they take it into account in their designs, but space is so tight

to begin with that some of the sensors push the limits here. So you

might find it difficult to make everything fit.

There are two tricks that can help. The first is that you can mount

the switches sideways or diagonally, instead of vertically as shown in

the illustrations above. That can help get them out of the way of the

moving plunger parts. I'd treat this as a last resort, since sideways

mounts can create other conflicts (with the TV or apron, for example).

The second trick only applies if you're using the VirtuaPin switch

holders. If so, then your flipper buttons are extra-long, and you can

swap them with shorter ones. The VirtuaPin switch holders only fit

onto 1-3/8" buttons, whereas most modern commercial pinball machines

use 1-1/8" buttons. So if you're using the longer buttons, you can

save 1/4" by swapping them for the more common 1-1/8" buttons. The

downside is that this requires ditching the VirtuaPin switch holders,

which are convenient, and instead mounting the leaf switches to the

cabinet wall as described above.

Adjusting the leaf switch gap

Most people in the pinball world agree that leaf switches are the only

thing that feel right for flipper buttons, so they're almost

obligatory in a virtual cab. But they do have one downside, which is

that they sometimes need a little mechanical adjustment to get the

switch blades aligned properly. Good operation depends on having just

the right gap size between the contact points.

I wouldn't worry about making adjustments when first installing brand

new leaf switches. I'd start with the assumption that they were

aligned correctly at the factory. However, once you start using the

buttons, keep an eye out for any flaky behavior: missed presses,

random flipper flipping while holding a button down, weird

auto-repeats, etc. If you see anything like that, you can take a

closer look at the switches to see if they need adjustment. You might

even have to re-adjust them from time to time, although in a home-use

cab I wouldn't expect having to do that more than once every couple

of years.

Whatever you do, don't clean the contacts with anything

abrasive. You might see advice in "real pinball" contexts about

sanding or scrubbing leaf switch contacts to remove oxidation. That's

only for real pinball machines with high-voltage leaf switches, which

use tungsten contact points. For a pin cab, it's better to use

switches with gold contact points, since those work better for low

voltages. Abrasive cleaning is bad for the gold contacts since it can

remove the thin gold plating layer. The main reason that you see

people recommend harsh scrubbing for the old tungsten switches is that

tungsten oxidizes over time (especially in the presence of constant

electrical switching), and the oxide layer is a good insulator, so you

have to periodically scrape it off. Gold doesn't oxidize, so

gold-contact switches don't tend to need much cleaning in the first

place. But if you think your switches do need cleaning, use a

slightly damp soft cloth and rub gently.

Testing: If you suspect flaky behavior from your leaf

switches (or any other switches), but you're not sure, you can use

the Pinscape Config Tool to take a closer look. (Assuming you're

using Pinscape as your key encoder - if not, check your key encoder's

instructions to see if it has a similar testing function.)

Fire up the Pinscape Config Tool, and click on the Button Tester

icon on the main screen. This will bring up a window that gives

you a direct view of each button switch at the hardware level.

For the button or buttons that you suspect,

press and hold the button and observe the status shown in the

tester window. If the button is working properly, the on-screen

status should show a nice, steady "On" indication, without any

blinking or flickering. If you see the "On" indication flicker

at all, you should try adjusting the leaf switch as described

below. Likewise, when you release the button, the on-screen

display should show a solid "Off" indication.

Tools: This is one of those jobs where you really need

a special-purpose tool. The right tool makes this otherwise

quite difficult job pretty easy. The right tool in this

case is a "leaf switch wrench", which is essentially a little metal

rod with a slit in one end that fits over a switch leaf and lets you

bend the metal by a precise amount at a precise point. You can buy

these from pinball vendors. On Pinball Life, search for "Ultimate

Leaf Adjuster Tool". I bought one of those a while back

for work on my real pinball machines, and I highly recommend it.

Dennis Miller on vpforums

sent me a great description of how he created his own leaf switch tool

from scratch, so I'll pass that along in case you'd like to

build one yourself as well:

All leaf bending needs to be done with the proper tool. I made mine

out of 1/8" steel rod. I cut a slot 1/2" deep into the end of the rod

with a hacksaw. I then heated and bent the rod at 90 degrees just

above the slot so that the slot was almost parallel to the shaft.

Slide the tool's slot over the leaf at its base insulator stack and

bend very gently, a little at a time, to coax the leaf into position.

The off-angle slot enables working close to cab walls.

How to adjust: Approach this as an iterative process. Make

small adjustments, test, and adjust again as needed. Make your bends

towards the bottom of the leaves, close to the insulators.

- Start with the leaf on the button stem side. Adjust it so that it just touches the button stem when the button is at rest. There shouldn't be any open gap between the button stem and the leaf, so that the leaf starts moving the instant you start pressing the button. But don't overdo it; you don't want the leaf exerting too much extra pressure on the button, as that will make the button feel too stiff. The button already has its own spring for tensioning.

- Once the button side leaf is adjusted properly, adjust the other leaf so that the gap between the contact points is between 1/16" and 1/8".

- A 1/16" gap will make the button engage after pushing it in by about a quarter of its total travel. 1/8" is closer to the halfway point. I think the ideal point is a matter of taste, so test how it feels to see what you prefer.

- Once you've decided on the preferred gap size, you should adjust all of the flipper and MagnaSave buttons to use the same gap, to give them a consistent feel.

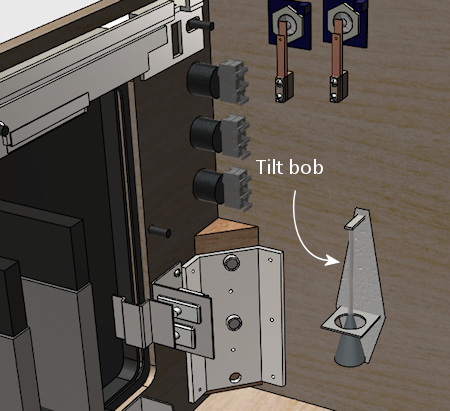

Tilt bob

The tilt bob conventionally goes at the front left corner of the cab.

The exact placement isn't critical; just mount it in some free space

below the left flipper buttons. Be sure to leave enough space that

you'll be able to work on the wiring to the front buttons and coin

door.

If you buy your tilt bob as a pre-assembled unit with its own mounting

plate, mounting it is just a matter of screwing the mounting plate to

the cab wall. It's almost as easy if you don't get the assembled

version, though; you just have to mount the pendulum bracket and

the contact ring separately, in the same arrangement as used in

the pre-assembled units. See the illustration below.

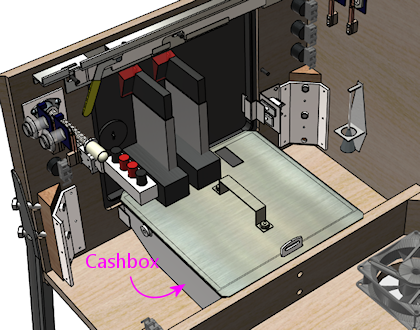

Cashbox

This isn't something you have to "install", exactly; it just drops in.

But the standard type does take up a big chunk of space, so if you're

using that, you might want to keep it in place (or keep it handy)

while you're doing your space planning so that you take its bulky

presence into account.

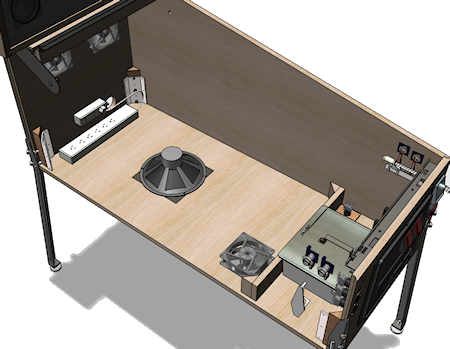

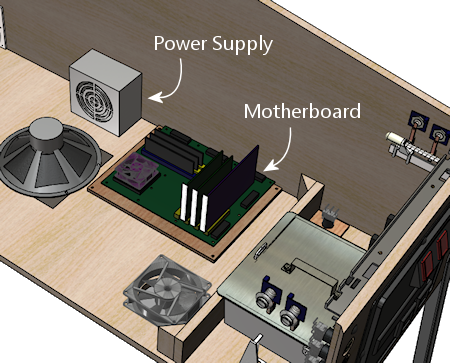

PC and PSU

We're just about out of the standard "real pinball" parts, so let's

turn to the virtual part of the system. I'd start with the PC, since

it has a fairly large footprint.

Let's look at what we have available, now that we've taken into account

most of the items that have to go at pre-determined locations:

Given this layout-so-far, there's an obvious place where something the

size of an ATX motherboard or enclosed PC case would need to go:

We have a little flexibility with the power supply, but only so much:

it has to be close enough to the motherboard that the power cables for

the motherboard and video card can reach their sockets. The obvious

place is just behind the motherboard. That also happens to take good

advantage of the space there, which is somewhat constrained by the

presence of the subwoofer.

Setting up the PC hardware is a fairly significant project in itself,

so we give that its own chapter, Installing the PC. That section

covers other ways of installing the PC components, such as enclosing

them in a conventional desktop case, and goes into more detail about

choosing a location and implementing the installation.

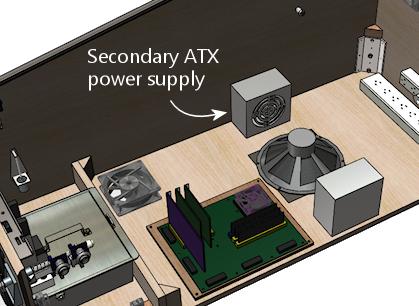

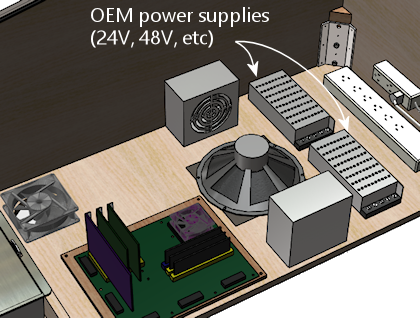

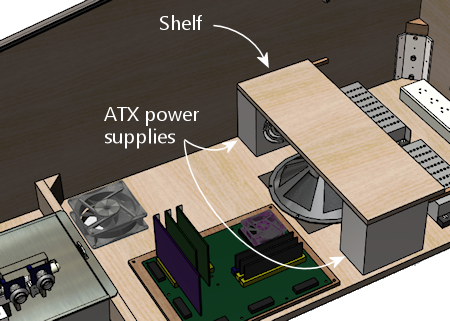

Secondary power supplies

If you're installing feedback devices, you'll need to install power

for them. More details can be found in Power Supplies for Feedback, but

the executive summary is that you can generally cover most of the

bases with ATX power supply (that is, a separate unit of the same type

used for the PC motherboard's power supply) and one or two generic OEM

power supplies for higher voltages (such as 24V and/or 48V).

For the secondary ATX PSU, a good location is the mirror image of

where we placed the PC power supply: on the other side of the

subwoofer. Assuming you centered the subwoofer, there's a nice

ATX PSU-sized space on either side, so we might as well use it

that way.

The typical OEM power supplies come in long, low cases that fit well

into the space remaining at the back of the cabinet, between the

subwoofer and the power strips.

The OEM supplies are usually a good physical fit for this space, and

they're also a good functional fit, in light what I said earlier about

how the back section becomes increasingly inconvenient to work in as

you build out the cabinet. The power supplies are a good

set-it-and-forget-it kind of thing for a hard-to-access space. They

don't have any controls; you just plug them into power.

You do have to be able to access their power outputs, though,

whenever you want to plug in a new device. So there's a bit of

advance planning you should do when you install them. Specifically,

you should wire their outputs to connectors located somewhere more

accessible in the cabinet, more towards the front. Many people set up

a group of terminal strips like the one illustrated below somewhere

readily accessible, one for each voltage level, so that they can

easily connect each new device to its appropriate supply when the time

comes. (Be sure to protect any exposed terminals like these with

plastic covers, so that loose wires don't accidentally inject high

voltages into unsuspecting logic boards.)

A nice side benefit of installing the two ATX power supplies across

the aisle from one another is that we can use them to construct a

little shelf across the width of the cabinet. That'll be useful

later: you can see that the floor space is already almost all gone,

and we still have a number of important things left to find room for.

If you've been paying attention, you know how important I think it is

that you be able to access everything in the cabinet even after it's

fully assembled - the principle I call serviceability. So you should

be sure that this shelf can be easily removed! Don't glue it in or

anything like that. At the very least, fasten it with a couple of

easily removable screws. But better yet, use something you can undo

without tools: attach it to the power supplies with Velcro, for

example, or use toggle latches to lock it down. That way it'll only

take a few seconds to remove it if you have to get to the power

supplies.

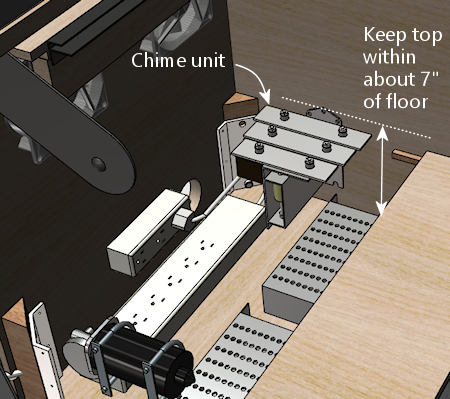

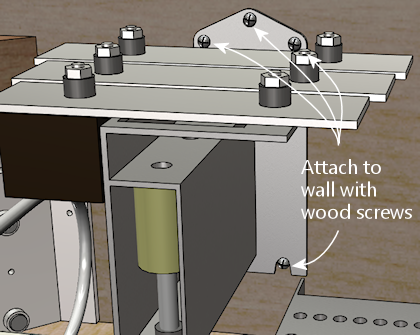

Chime unit

See Chimes and Bells. This is a little percussion instrument that

replicates the iconic bings and bongs of the electro-mechanical

pinballs from the 1960s and 70s. The best way I know to accurately

reproduce the original sound is to find an authentic used chime unit

from an old machine, as they have some engineering that's hard to

replicate in a DIY design. The real units are quite bulky, though,

which limits where we can put them. The only place where a chime unit

will fit in our hypothetical fully-loaded cab is in a corner at the

back.

The original chime units are designed to be mounted to a side wall.

Use wood screws to attach it via the integrated mounting plate.

Try to keep the top within about 7" of the floor. This will help

avoid any clearance issues with the back of the TV when you lift it

up. (Assuming you opt for a liftable TV mounting, as outlined in

Playfield TV Mounting.)

Much as I don't like hiding things away in the back of the machine, we

really don't have much choice when it comes to the chime unit.

There's just not enough space anywhere else. If your cab won't be as

fully loaded as the one we're developing here, though, you might have

some space for it in a more convenient area, so by all means put it

somewhere better if possible. I don't think the placement makes any

significant difference acoustically. For what it's worth, most of the

original machines that used these units also placed them in a corner -

typically the right front corner, below the plunger.

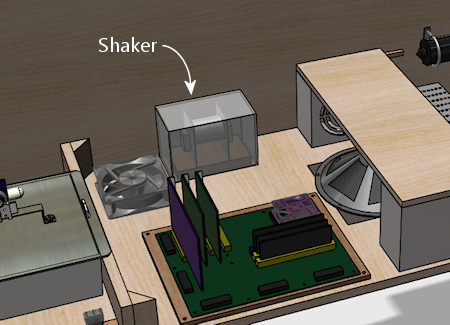

Shaker

See Shaker motors. The shaker is another bulky toy, and in this

case it must be mounted on the cabinet floor to get the proper

effect. Fortunately, we have one large floor section still remaining,

mid-cab, opposite the PC motherboard.

Happily, this works out well, as this is just about exactly where we'd

put the shaker anyway, to get the best tactile effect, if space were

no concern. You want the shaker to be mounted with its motor axis

parallel to the cabinet's long axis, and that's a perfect fit for the

available space. You also want the shaker to be in roughly the middle

of the cab front-to-back so that it imparts a balanced sideways

motion. There's no benefit in centering it side-to-side, so I'd mount

near the wall, to leave more room around the PC for cable connections.

Gear motor

See Gear motors. These are meant to reproduce the sound of

the motorized playfield features on many pinballs from the 1980s and

1990s, such as Thing from The Addams Family or the castle gate

from Medieval Madness. To localize the sound effect properly,

the gear motor should be somewhere towards the back of the cabinet,

since the playfield features it's meant to imitate are typically

towards the back of the playfield. (The playfield features in

question are all unique to each game, so they're all in their own

unique locations, but for the most part they're somewhere near the

center rear of the playfield.)

There are two rather different types of motors that pin cab builders

tend to use for these. One type is the small robotics servomotors you

can buy on eBay. Those are so compact that space planning really

isn't an issue for them. The other popular type is an automotive

windshield wiper motor. Those are quite a lot larger, and do require

that you block out some space for them. We'll proceed with the

assumption that you're working with the larger type and need to find a

place for it.

If you're using a liftable TV frame design, you might be able to mount

the gear motor on the bottom side of the TV frame. That would let you

put it right in the middle of the playfield area, which is the ideal

location for the sound effect, plus it's easy to access for service.

This is the right option if you have a compatible TV mounting.

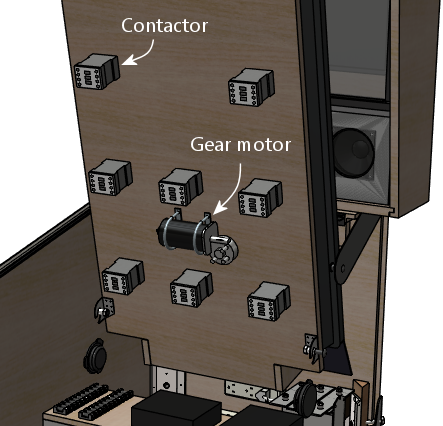

In the illustration above, we're assuming that the contactors for the

bumpers and slingshots are also mounted under the TV. A gear motor

should fit nicely between the "bumper" rows in the back half of the

playfield. See "Mounting contactors under the TV"

below for more about this.

If an under-the-TV mounting doesn't work in your cab, there are

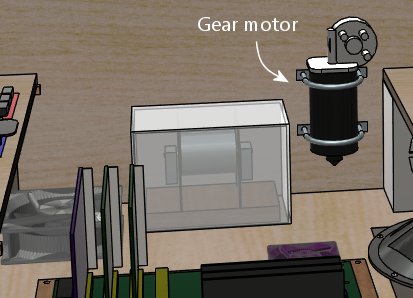

several places it might fit. One possibility is to place it alongside

the shaker:

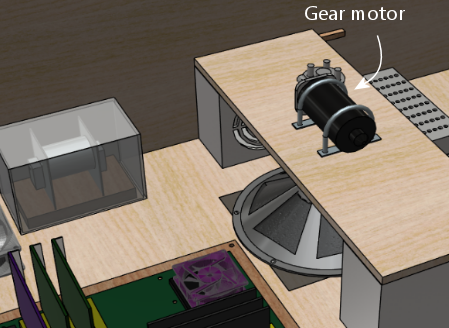

A second option is to use the little shelf we built over the ATX

power supply and subwoofer area:

The shelf is probably the best location in terms of localizing the

audio effect, and it's a great location in terms of service access.

The only problem is that there are a couple of other devices we'll

come to later that we'll need the space for. So we're not

going to be able to leave it here in the model we're developing, but

you can keep this location in mind as an option in your cab, if the

space ends up being available after you consider where the rest of the

parts go.

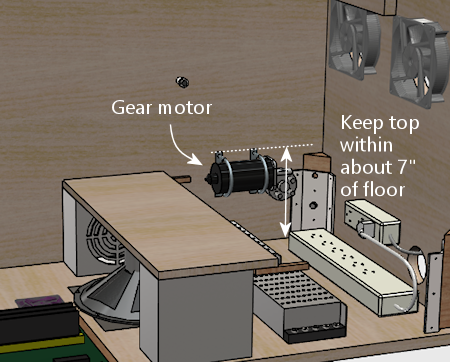

A third option is to place it in a corner at the back:

If you go this route, try to keep the top within about 7" of the

floor. This will help avoid any clearance issues with the back of the

TV when you lift it up. (Assuming you opt for a liftable TV mounting,

as outlined in Playfield TV Mounting.)

As I've said a few times, this isn't a great area to mount just about

anything, because it's hard to reach into in an assembled cab. But

gear motors tend to be zero-maintenance, so if you have to put

something back here, a gear motor isn't the worst choice. What I'd

recommend is to use a mounting apparatus that you can remove without

tools if necessary. Something like this, perhaps:

- Mount the motor to a small sheet of plywood (cut just large enough for the job) with a pair of "U" clamps, which you can buy at any hardware store

- Use something like a Z-clip (a heavy-duty type of picture hanger) to hang the plywood carrier on the wall

- Secure the bottom with a thumb screw or toggle latch, so that it can't come loose from the hanger

If you do need to access the gear motor, this will let you take it out

as a unit without having to do anything too complicated in the

confined space. Once it's out, you can make whatever changes are

needed, and just as easily put the whole unit back in place.

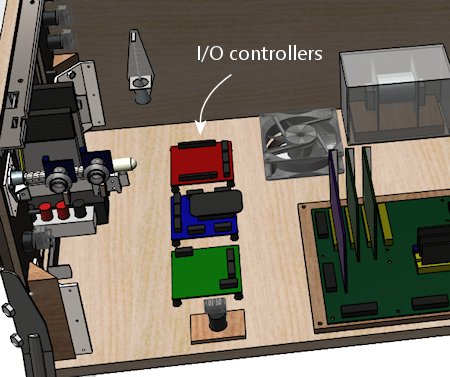

Controllers

See I/O Controllers. A pin cab requires some special USB

devices to connect the button inputs, plunger sensor, and feedback

devices. There are several options for these, but whichever you

choose, you're going to have some little circuit boards that you'll

need to mount somewhere in the cab. Most cabs need two or three

boards, most of which are on the order of 4" by 4".

Most of these boards can go just about anywhere that's convenient, but

there's one type of board that's pretty particular about location: the

accelerometer, also known as the nudge sensor. That board should be

mounted horizontally, close to the front of the cab, preferably close

to the center of the cab. The accelerometer senses the cabinet's

motion, and it does the best job at that if it's mounted in a central

location near the front.

If you're not using a full-sized cashbox, then you still have a

nice open space at the front, where the cashbox would go on a real

machine. That's an ideal spot for the controllers.

If you are using a full-sized cashbox, we're in a bit of a jam

now, because there's enough floor space left for the controllers.

This is, in fact, why I don't have a real cashbox in my own cab. But

I don't really like my hokey improvised substitute (a plastic food

container that happens to be about the right height, with holes cut in

the lid to line up with the coin slots). So given that this section

is about an idealized ultimate cab with everything, let's see how we

could make this work.

My proposal is basically to create some new floor space, by

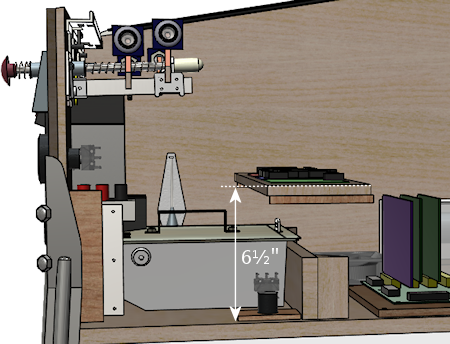

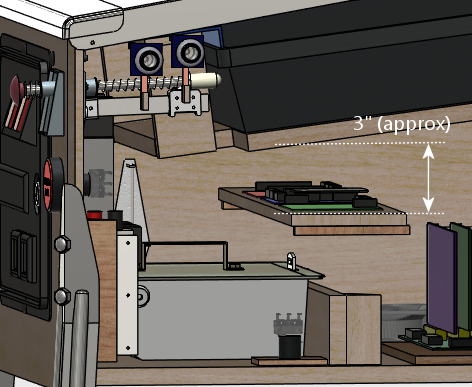

thinking three-dimensionally:

What you're looking at is a shelf, running the width of the cabinet,

about 6½" above the floor, positioned over the back portion

of the cashbox.

This reclaims the floor space that we gave up to the cashbox. It's at

the right position for our accelerometer, and it gives us enough space

to mount a typical complement of I/O controller boards.

Some important considerations:

- For the sake of the accelerometer, the shelf must be quite solid, and quite solidly mounted to the cabinet. It must move with the cabinet; it shouldn't impart any extra vibration or wobble of its own. For this reason, I think this shelf needs to be securely screwed in, not held down with Velcro or anything like that. But I think it's okay for this shelf to be more or less permanent, since, if it's properly positioned, it won't block access to anything.

- Position the shelf so that it doesn't block access to the motherboard. This is especially important given that it needs to be so solidly (permanently) attached to the cabinet.

- Use a sturdy material. I'd recommend a good quality 3/4" hardwood plywood, the same sort of material used for the cabinet itself. The shelf doesn't have to support any significant amount of weight, but remember that we want it to be very solid so that we get good accelerometer readings.

- At the recommended height, the shelf will leave enough space that you can still conveniently maneuver the cashbox in and out through the coin door, as intended.

- At this height, the shelf should also leave comfortable clearance for a typical playfield TV with my recommended mounting. For the purposes of the model, I assumed what are probably the worst-case conditions in terms of how much headroom we have here: a fairly thick TV (3.5") and a "deep" mounting style (with the TV at full playfield depth). With those assumptions, we still have about 3" of headroom to work with here. That's plenty of space for any of the controllers I've encountered.

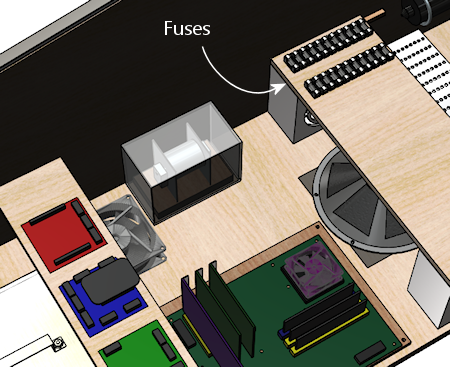

Fuses

See Fuses. Fuses can be used to protect your output

controller from overloads. You don't necessarily have to include a

fuse for every device, but it's good to cover the higher power

devices, such as motors and solenoids.

Your output controller might have its own built-in fuse holders, but

most of them don't, so fuses usually have to be installed separately.

We're going to assume you're installing them separately.

There are many types of fuses and fuse holders. For my own cab, I

went with the type that's common on the real pinball machines (not for

the sake of realism, but just because it saved me the trouble of

researching all of the other options). Those are the so-called 3AG

glass cartridge fuses, which look like this:

These can be used with little plastic holders that look like this:

This type of holder is designed to be mounted to any sort of surface

with a screw (which you can see in the photo), so we can mount these

on any convenient wood surface on the cab, such as the floor, a wall,

or that center shelf we created earlier over the ATX power supplies

and subwoofer:

I like the idea of centralizing the fuses in one big set like this,

since it makes it easier to find the fuse for a given circuit.

However, it has some disadvantages: it takes up a big block of space,

and it requires extra runs of wire to and from the central fuse panel.

You also have to make a chart of what each fuse is connected to.

Another option that you might prefer is to place each fuse near the

device it's connected to. The individual fuse holders are small and

can mount just about anywhere, so ad hoc placement per fuse avoids the

need to allocate space for a central fuse panel. And it can save a

lot of wire, since you can place each fuse somewhere along the section

of wire that you'd have to run out to the device anyway. Finally, it

might be easier to figure out which fuse goes with which device this

way, as long as you can manage to place each fuse physically close to

its device.

Keep in mind that the type of fuse holder pictured above has two

exposed metal terminals. If you're creating a central fuse panel out

of these, you should consider placing a plastic cover over it to

protect it from accidental contact from tools or loose wires. If

you're scattering the fuses (rather than creating a central panel),

you might want to use a more fully enclosed fuse holder instead of the

open type. For example, take a look at the Littlefuse 155 series

in-line twist-lock holders. Those are designed so that there are no

exposed terminals.

Littlefuse 155 series in-line 3AG fuse holders

Contactors (and other solenoid simulators)

See Flippers, Bumpers, and Slingshots. The real pinball machines have a lot of

powerful solenoids that kick the ball around and actuate other

playfield mechanisms. They're are strong enough that you can not only

hear them but feel the kick. Virtual pinball software can manage the

audio part with recorded audio, although that tends to be a weak

imitation that you'd never mistake for the real thing. In a pin cab,

we can do better, by simulating the kick of the solenoids with actual

solenoids. That can get a lot closer to the real sound, and can also

reproduce the tactile effect.

There are several types of solenoid-based devices that pin cab users

employ as substitutes for pinball solenoids: contactors (such as the

Siemens type pictured below), automotive starter relays, generic

open-frame solenoids, and even real pinball solenoids and their

associated mechanisms.

Common devices used to simulate pinball coil effects: Siemens

contactors; Ford starter relays; generic open-frame solenoids.

For the purposes of our illustrations, we'll use the Seimens

contactors. The Ford starter relays and most open-frame relays should

comfortably fit the same spaces, so you should be able to substitute

them without making other changes.

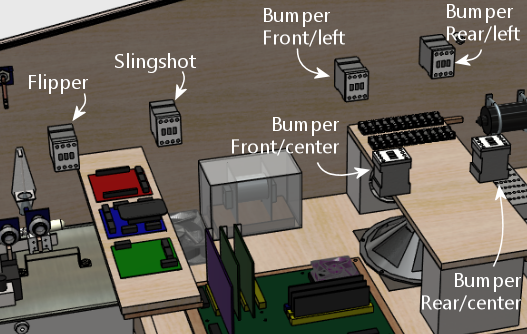

The standard complement of contactors consists of 10 units:

- Two flippers (left and right)

- Two slingshots (left and right)

- Six bumpers (three across the middle, three across the back)

The goal is to locate each contactor so that it matches up with the

position of the device it's intended to simulate, as it'll appear on

the main TV screen when you're playing a game. So you want the

contactor that's going to serve as the "left flipper" to line up

roughly with where the simulated left flipper is drawn on the TV

screen. It's obviously impossible to get that perfect for every game

when you're going to have hundreds of simulated games to choose from.

But all pinball playfields tend to follow the same template for the

core elements around the flipper area, and anyway, we don't have

to get it perfect, just close enough to be convincing.

So, taking the desired positions into mind, here's how we can

arrange the ten devices to fit the available space. Note that

the devices illustrated on the left wall are mirrored on the

right wall, but we're leaving them out of the diagram for the

sake of readability.

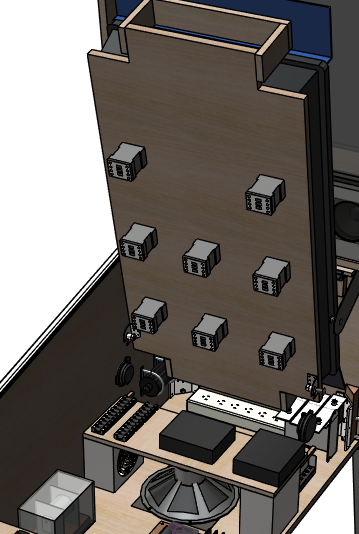

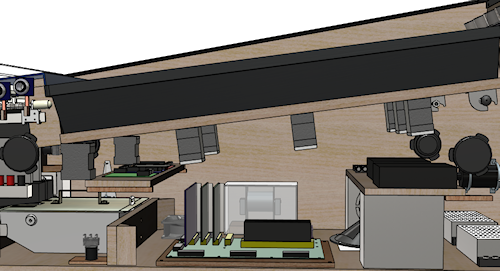

Mounting contactors under the TV

If you're using a liftable TV mounting like the one described in

Playfield TV Mounting, you can move most of these to the

bottom side of the TV mounting frame, as illustrated below.

Here we've moved all of the contactors except the flippers to the

underside of the TV frame. We left the flippers where they were (on

the side walls), because the natural place for them on the TV frame is

a bit too close to the shelf where the I/O controllers are located.

If we didn't have that shelf, we could easily move the flipper

contactors to the TV frame as well. This is what it looks like

when we lower the TV back into its normal position:

As you can see, there's lots of room for everything, except for

the area around the I/O controller shelf.

The under-TV mounting style has some distinct advantages:

- It places the devices closer to the on-screen elements they're intended to simulate

- It frees up space along the cabinet walls

- There's more room for larger devices than the original side-wall mounting

- The contactors are easier to access for service, since they're more out in the open after you lift the TV up

I don't think there are any real disadvantages, either. I think it's

the right way to go if you have a suitable TV mounting. And it's

practically required if you plan to use real pinball mechanisms for

any of the solenoid devices; they're too large to be workable with the

side-wall mounting.

There is one important consideration if you go this route. You'll

definitely need to use a pluggable connector for the wiring to the

contactors, so that you can remove the whole TV-and-frame assembly

from the cab without having to cut wires. I recommend using one

of the Molex .062" wire-to-wire connectors, which are available

in plugs with up to 12 pins. That lets bundle the wiring for the

whole set of contactors into a single plug.

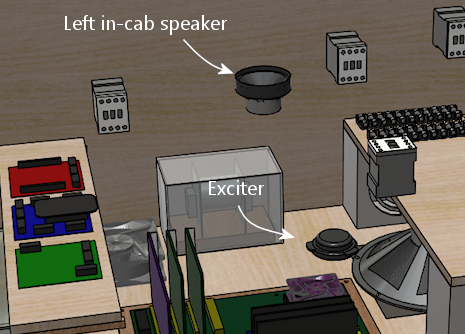

In-cab speakers

See Audio Systems. We've already covered the subwoofer, which

traditionally goes on the floor in the middle of the cab. But many

cabs also include a set of mid-range speakers inside the main body.

These are usually in addition to the speakers in the backbox,

and serve a different purpose. The backbox speakers are there to play

the ROM music and voice effects. The speakers in the cab are there to

reproduce mechanical sounds that aren't already covered by the

solenoids and contactors. For example, the sound of the ball rolling

and bumping into things.

Visual Pinball has the ability to separate the music from the

mechanical effects and play each type of through a separate set of

speakers. Playing back the mechanical effects through speakers inside

the cabinet makes them seem to come from the playfield, improving the

illusion. VP 10 takes this one step further, by supporting a

four-speaker "surround sound" arrangement that localizes each sound

effect to the right point in the playfield plane.

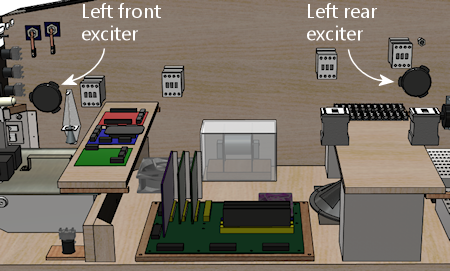

There are several ways to configure in-cabinet speakers. If I were

building a new cab today, the only option I'd consider would be a

four-exciter system. This takes advantage of VP 10's spatial

localization capability to position effects in different parts of the

playfield.

An "exciter", by the way, is a type of speaker that works by making

the surface it's attached to vibrate. A conventional speaker works by

vibrating a paper cone. An exciter uses whatever it's attached to in

place of the paper cone. They're better than conventional speakers

for an in-cab speaker system for several reasons:

- They're much smaller than regular speakers, so it's easier to find room for them in a crowded cab

- They're made specifically to be mounted to flat surfaces (like the wall of a pin cab!)

- They work by transmitting their sound energy through whatever they're attached to, which better reproduces the way mechanical sounds in a real pinball machine travel through the cabinet

- Transmitting the sound through the cab wall produces more of a tactile effect than a regular speaker does

The ideal mounting positions are at roughly the corners of the TV.

That's the arrangement that the VP software assumes when it calculates

the volume mixing levels to create the illusion that the sound is

coming from a particular point in space. It's pretty simple to

install exciters this way: just install two on each side wall,

below the TV, one near the front and one near the back. Most

exciters are quite flat and compact, so it's not hard to find

room even with everything we've installed so far.

Some people add one or two subwoofers to this setup as well. I

personally don't think that's necessary. For the types of sound

effects we're talking about in a pin cab, the only reason you'd want a

subwoofer is for more of a tactile effect. Exciters are already good

at producing tactile effects because of the way they transmit the

sound energy through the cab wall, so I think a subwoofer is

redundant. Besides, if you really need more bass from these channels,

you can make Windows mix the low-frequency bands from the surround

channels into the main subwoofer output.

I built my own cab before VP supported the four-channel surround

system, so I took a simpler approach, with two regular speakers and

tactile subwoofer:

This produces a decent effect, certainly better than no in-cab

speakers at all, but the lack of spatial positioning is sometimes too

obvious. It's particularly noticeable when the ball is near the top

or bottom of the playfield, since the sound always comes from a fixed

spot in the middle. That's why I'd go with the four-speaker system

now that it's an option.

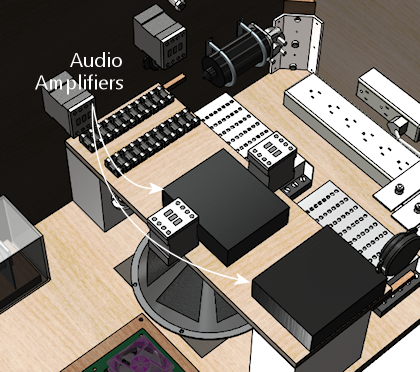

Amplifiers

See Audio Systems. Unless you're using powered speakers, you'll

need some amplifiers. Most pin cab builders use small car amps, since

they're compact and (like everything automotive) run on 12VDC power.

Most of the cheap units can power a stereo speaker pair or a stereo

pair plus subwoofer (the latter being known as a 2.1-channel amp).

Many higher-end car amps can power four independent channels.

You'll typically need the following:

- One 2.1 amp for the backbox speakers + main subwoofer

- A second 2-channel or 2.1 amp for the front surround speakers

- A third 2-channel or 2.1 amp for the rear surround speakers

I've been keeping space for a couple of these units open on the

shelf over the subwoofer area:

What you can fit here will obviously depend on the specific equipment

you choose. You can probably fit two small car amps, and maybe three,

if you're able to stack two of them vertically.

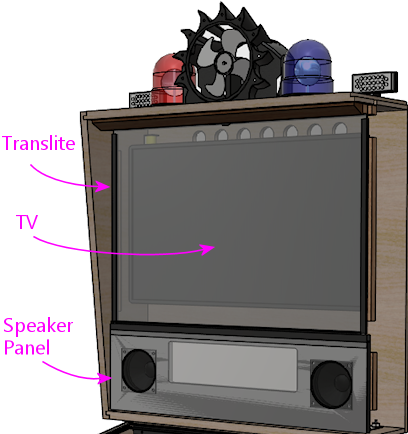

Backbox

In the backbox, as in the main cabinet, we have a top layer that's

visible to the player. In the backbox this consists of the translite,

backglass TV, and speaker/DMD panel.

Those are all covered in detail in other sections:

- "Creating a translite" in Backbox Hardware Installation

- Selecting a Backbox TV (designing the backbox layout and choosing a backbox TV)

- Backbox TV Mounting (installing the TV)

- Speaker/DMD Panel (fabricating and assembling the speaker/DMD panel)

There are some additional items that we can fit into the backbox, mounted

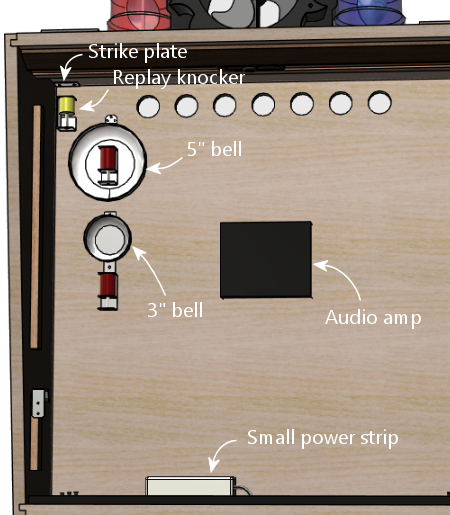

on the back wall.

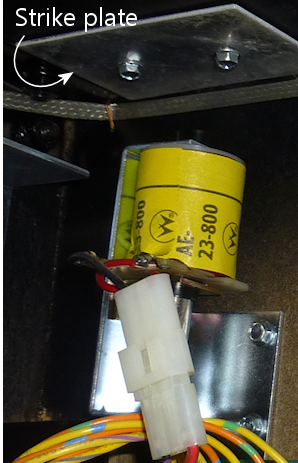

- Replay knocker: typically mounted at the top of the backbox in a corner. The knocker coil is mounted so that the open end points up at the ceiling, with about a 1" gap to the ceiling. The metal strike plate is mounted on the ceiling right above it. See Replay Knockers.

- Shell bells. If you're a big fan of machines from the electro-mechanical era, you can install a couple of round bells with solenoid hammers. Similar bells were used in many machines from the 1960s and 70s. These serve exactly the same function as chimes, so in a way they're redundant with a chime unit, but the reason you might want to have both is that bells and chimes each have their own distinctive sound. Some games from the EM era had bells and others had chimes, so you can more accurately re-create a greater variety of games if you have both. The backbox is a good place to install bells if you have them; the bells have a large footprint, but they're flat enough to fit behind a TV (in most cases, anyway), so this takes good advantage of the wide but shallow space in the backbox. As a nice bonus, it's true to the originals: it's where bells were usually situated in the EM machines. See Chimes and Bells.

- Repeating bell (not shown). The shell bells above work like chimes in that they fire with one hammer strike at a time. There's a different kind of bell used on some machines from the 1980s, which rings continuously when energized, like an old-fashioned alarm clock or telephone ringer. These look just like the shell bells, so they're an equally good fit for this space. There should be plenty of room to add one of these if desired. See Chimes and Bells.

- Audio amplifier. We already proposed a place where you can fit a couple of car-radio amplifiers into the main cabinet. You might also be able to fit an amplifier into the backbox, either as an alternative to the main-cabinet mounting or in addition (which might be necessary if you need four channels of audio in the main cab for a surround-sound setup). You'll probably have about 1" to 2" of depth to work with behind the TV, which is enough to fit a small amplifier.

- Power strip. There should be enough space on the floor of the backbox behind the DMD panel to install a small power strip. A 3-outlet strip fit easily in my backbox in this area. It's convenient to have a few outlets here, so that you can plug in the backbox items (TV, DMD panel, audio amp) without having to run more cables through to the main cabinet.