30. Backbox TV Mounting

Continuing the theme of installing our TV screens, we turn now to

installing the backbox TV.

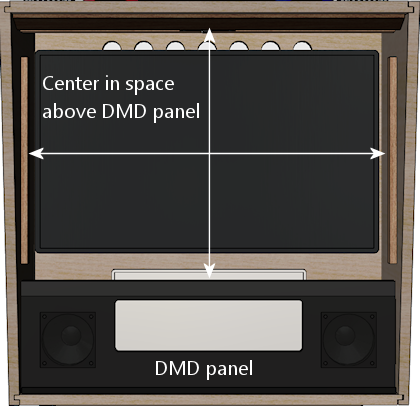

Positioning the TV and light-sealing

I recommend positioning the TV so that it's centered in the space

above the speaker/DMD panel.

If you're using a translite cover, I'd try to position the front

surface of the display so that it's flush with the translite, or as

close to flush as you can make it. That will make it look very much

like the artwork is being displayed on the back of the glass/acrylic,

which looks just like the real thing.

On my machine, I put strips of black felt around the perimeter of the

display bezel (fastened with double-sided tape). This lets the

translite be right up against the monitor face without too much risk

of scratching it, and it also forms a nice light seal around the

perimeter.

The Jersey Jack Pinball approach

The WPC-era machines didn't have anything resembling a full-sized TV

in the backbox, so there's nothing we can directly adapt from their

design or hardware to mount the TV. But if we widen our scope beyond

the post-WPC era, we can find one example from the real pinball world

that's very similar. Jersey Jack Pinball, maker of Wizard of

Oz (2013), The Hobbit (2016), and a few other titles, uses

a 27" LCD panel in the backbox in place of the WPC-era DMD. They even

install a translite (with a cutout for the TV) in front of the panel,

so it's almost exactly like the typical virtual cab setup. The only

difference is that they place the panel at the bottom of the backbox,

whereas we typically place it near the top, so that we can also put a

traditional DMD-sized display in the speaker panel area. But that

difference in placement doesn't affect the mechanics of the mounting.

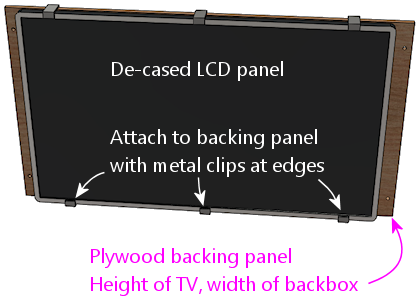

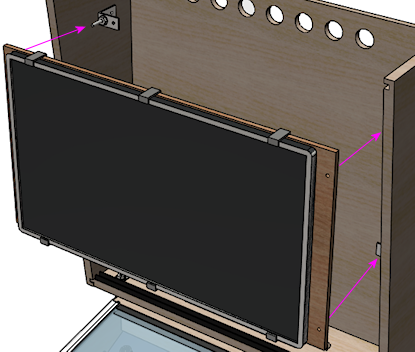

Their approach to mounting the panel is straightforward. They start

with an uncased OEM display panel, and mount it to an MDF backing board

with metal clips around the edges. For a virtual cab adaptation,

I'd use plywood instead, since it's stronger and lighter.

The backing panel is cut to the height of the panel, so that you can

easily fasten it with clips as shown. The width is the same as the

inside width of the backbox.

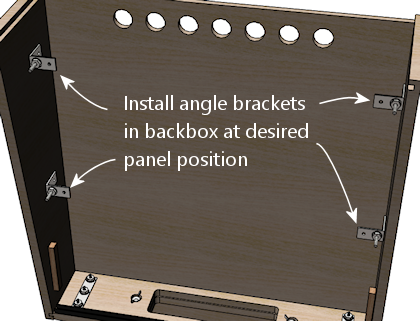

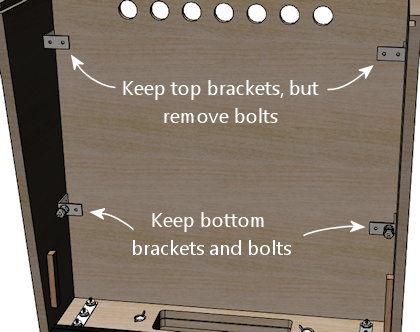

In the backbox, they install metal "L" brackets along the side walls.

These can simply be screwed into the backbox walls with wood screws.

The overall weight of an uncased panel plus plywood backing board

should be under 10 pounds, so each corner clip only has to support

a couple of pounds. So we don't need super-strong hardware here.

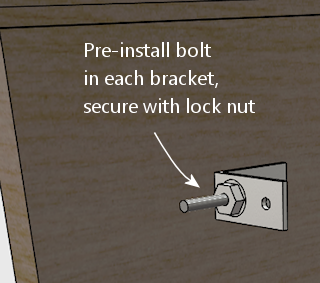

To facilitate installing the panel, pre-install a bolt in each

bracket, with the end pointing forward as shown below. Secure each

bolt with a lock nut.

Drill holes in the plywood backing to match the positions of the

pre-installed bolts. Installing the TV is now just a matter of

fitting the backing panel onto the bracket bolts. Secure it

in place with another set of nuts on the outside.

Some notes on this approach:

- When constructing the backbox, don't install the upper (15") translite guides. Those would get in the way of inserting and removing the TV panel. See "Translite/DMD guides" in Cabinet Body.

- You might replace the outer nuts with wing nuts, so that the TV can be installed and removed without tools. Better still would be some kind of quick-release latches - if you have any concrete ideas along those lines, let me know and I'd be happy to add pointers here.

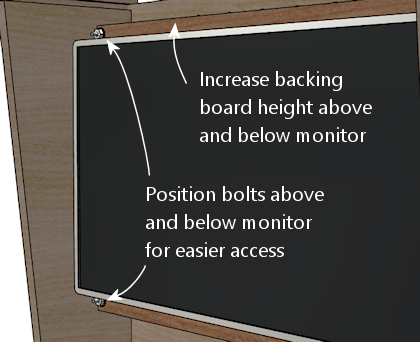

Adapting to a TV still in its case

This design works well with a bare, uncased LCD panel, but it requires

some changes if you're leaving the TV in its plastic case.

First, use the TV's VESA mounting holes on the back to attach it to

the plywood base, instead of the edge clips. You just need four M4

screws long enough to go through the plywood (probably 20mm to 30mm).

Second, with the added depth of a full case, it might be too

cumbersome to reach behind the monitor on the sides to fasten and

unfasten the nuts that hold it in place. So I'd move those so that

they're above and below the TV, where you'll have a little more room

to work.

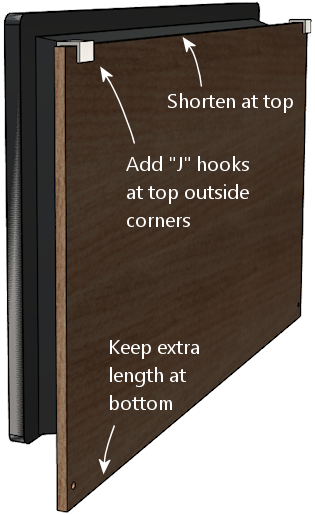

Further improving the design

Even with the bolts moved vertically above and below the TV in the

revised plan above, I think it's going to be a little cumbersome to

fasten those top bolts. The space above the monitor is quite tight

with a 28" display.

So I think the next step in improving this plan would be to substitute

some type of hanger hook at the top, such as a heavy-duty picture

hanger or "J" bracket. Or perhaps better yet, the latch bracket

used on the speaker/DMD panel (Williams/Bally 01-8535), which is

designed for this exact function with the speaker panel.

The bottom bolts are easy enough to access that we can keep those.

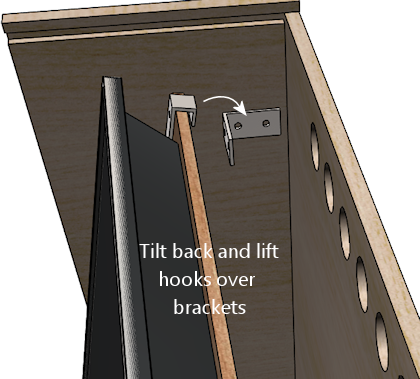

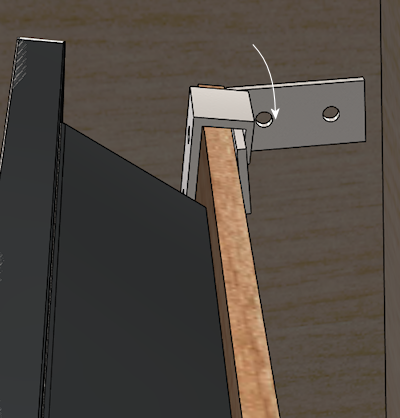

The new installation procedure would look like this:

- Tilt the monitor back slightly and fit into the hanger hooks at the top

- Lower onto the hooks

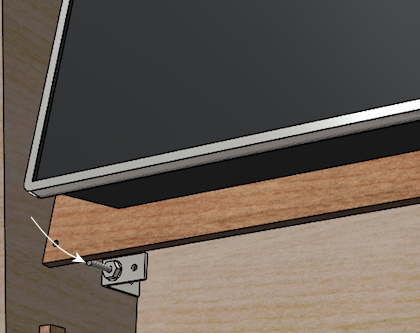

- Tilt the bottom onto the bottom bolts

- Fasten the nuts on the bottom bolts

I used a mounting similar to this on my own cab, and it works pretty

well. This should give you a little more than an inch of clearance

behind the TV for installing a replay knocker and EM-style shell

bells. You'll be able to access those devices for service if

necessary, since the TV can be removed fairly easily.

Fixed mounting

Another, easier way to mount a TV in the backbox is to more or less

build the backbox around the TV. You get the TV situated and bolted

down while the backbox is still being assembled, and then you finish

installing the remaining backbox walls.

There are different ways to go about this, but I've seen people use

procedures something like this:

- Start by building the backbox without its back wall

- Cut a piece of plywood to the interior dimensions of the backbox

- Fasten the TV to the plywood (via its VESA mount, for example)

- Fasten the plywood to the side walls at the desired depth, such as via "L" brackets or corner braces

- Install the back wall of the backbox

If you've read much else in this guide, you can probably guess that I

don't recommend any approach that would make it difficult to remove

the TV later. If you have to wait to finish the backbox assembly

until the TV is installed, you're going to have to reverse those last

assembly steps if you ever want to remove the TV, and that could be

difficult and destructive.

An argument could be made that it's okay that you can't remove the TV,

because why would you ever need to? Modern consumer electronics tend

to keep going for years and years without trouble. That's usually

true, but not always, plus it ignores the possibility that you might

need to access or remove the TV for some reason other than repair:

upgrading it to a newer model, say, or changing which video plugs

you're using.

There's also a potentially bigger problem: it'll be impossible to

access anything installed behind the TV without taking the back

off the backbox again. There's at least one part commonly mounted

behind the TV that you might at some point need to repair: the replay

knocker. This isn't a hypothetical risk, either. I've talked to a

couple of people on the forums who had to do major surgery - including

taking out nails and glue - to replace a dead replay knocker. So I

really strongly advise against any design that would seal up any

important components behind barriers that you can't remove, such as a

TV with a fixed mounting.

If you are using a fixed mounting, then, you might want to do one

of the following:

- Don't install anything behind the TV in the first place, so you'll never need to get back there. Treat the space behind the TV as a forbidden zone that no parts can set foot in. This solves the access problem, but you give up some prime real estate in the deal.

- Make the back wall removable, or build a big door into it. This restores access, but at the cost of significantly weakening the backbox. The fixed back wall is a key structural component.

I don't like any of these trade-offs, so I just wouldn't use a fixed

mounting like this.

Ideas from the real pinball world

What follows isn't a how-to plan, but just some food for thought.

I'm hoping someone can take the ideas here at some point and turn

them into a workable implementation plan. For now, though, these

are just some ideas.

The WPC-era machines didn't have anything quite like a backbox TV

that we can adapt in terms of mounting hardware, but they did have

something analogous that at least provides an interesting idea for

how a TV mounting might function.

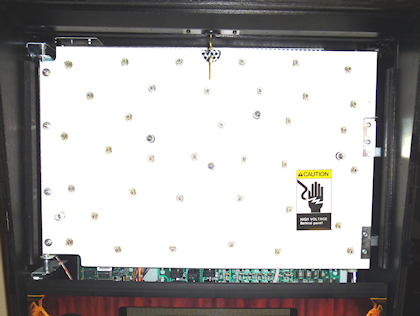

The WPC machines have something called a "backbox insert", which is a

sheet of plywood directly behind the backglass, holding the little

light bulbs that illuminate the artwork. This is exactly where

our backbox TV goes, so it's worth looking at how they installed this.

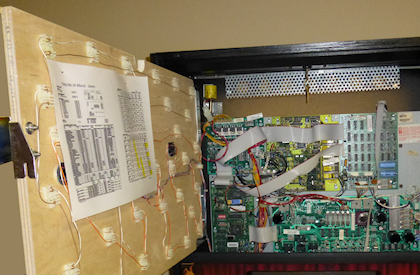

Backbox insert: a sheet of plywood installed just behind

backglass. The little spots scattered around are the lamps

that back-light the artwork.

On the WPC machines, all of the control electronics are mounted inside

the backbox, so you obviously have to be able to move the insert out

of the way for service work. The WPC design made this really

easy. You don't have to disassemble anything or even remove the

insert. It's attached with hinges on the left side, so you just swing

it out of the way like opening a door.

Backbox insert in open position. It's hinged on the left side

so that it can swing open like a door, to provide access to the

electronics installed behind it.

It would be great to be able to do the same thing with a TV - just

swing it out of the way when necessary, without even having to unplug

any video cables.

I'm afraid I don't have a How To plan to offer here to accomplish

this, though. My first thought would be to try to adapt the original

insert hinge hardware they used on the WPC machines, but those won't

work for a TV; they have the wrong geometry for anything deeper than

a sheet of plywood, and I don't think they'd be strong enough for

a 10-15 pound TV on a long lever-arm like this.

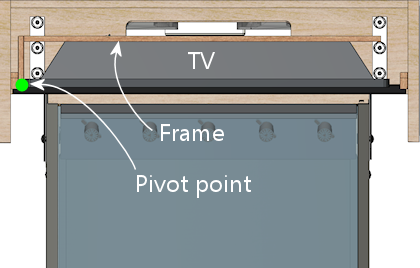

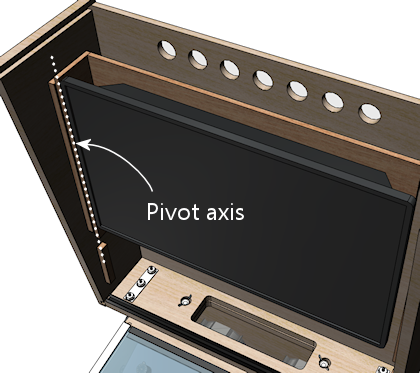

My next thought would be to look for some generic hardware that

could do the same thing, but I haven't found any. The sticking

point is the depth of the TV. To make the geometry work, we need

to place the pivot point at the front corner of the TV, and that

means that the TV itself has to be mounted on an articulated

platform. To use the TV's VESA mounting, this has to articulate

by the depth of the TV. The apparatus would have to look like this:

I think this can be done in principle, but I don't have a concrete

proposal for how to build it. I'm not sure how to make a TV platform

in that shape that would be strong enough. I don't think plywood is

strong enough, given that the full weight of the TV has to be

supported at that back left corner (in the illustrations). It might

also be challenging to find suitable hinges, although that's probably

just a matter of some legwork on Amazon, as there are lots of pivot

hinges available; there's probably something strong enough in the

right size.

If you can come up with a mechanism that would accomplish this with

generic hardware, please let me know! I'd be thrilled to be able to

include it in this guide. But for now, I'm going to say that a hinged

mechanism isn't practical for our purposes here.